Ultrasonic automotive wire harness welding machine The equipment parameters of the 3000W ultrasonic wire harness welding machine are as follows: HSW2030 basic parameters Working Frequency:20KHz Power capacity:3000w Working air pressure: 0.1-0.6 mpa Working voltage:220V /50Hz Welder size:520*200*320mm Welder weight:30KG Max welding section:25 mm² &nbs...

Ultrasonic automotive wire harness welding machine accessories four-piece Specializing in the production of ultrasonic welding heads, wire harness welding heads, four sets of welding heads, ultrasonic welding heads, ultrasonic molds, ultrasonic fixtures, ultrasonic horns, ultrasonic welding heads; 1.what is the ultrasonic horns: Ultrasonic horns are a generic term for all ultrasonic transmi...

Replace the ultrasonic metal welding step In the actual production operation, customers often face the situation of changing the ultrasonic welding head (mold) by themselves, so how can the welding head be installed quickly and without error? Let's learn it with me. (1)First, open the working air pressure source of the ultrasonic equipment to ensure the normal index of the equipment pressur...

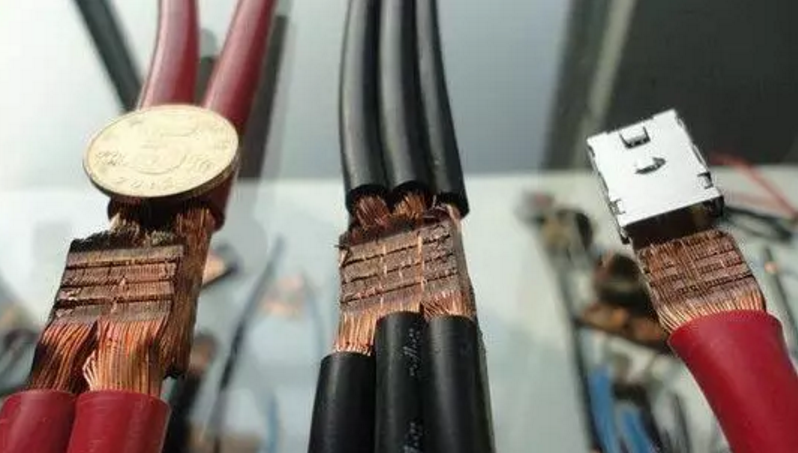

Multi-strand harness and 2mm terminal soldering Ultrasonic metal spot welding is applied to: metal wire harness, copper and aluminum wire harness, metal braided wire, metal stranded wire, metal guide wire, wire harness terminal, battery wire, wire harness forming, wire harness and thin rod, copper wire lead wire, multi-strand Copper wire, motor lead, terminal cable, connector harness, stranded cop...

Lithium Ion Battery Tab The Battery tab is a raw material for lithium ion polymer battery products. For example, the mobile phone batteries used in our lives, Bluetooth batteries, laptop batteries, etc. need to use the ear. The battery is divided into positive and negative poles. The battery ear is the metal conductor that leads the positive and negative poles from the battery core. Generally spea...

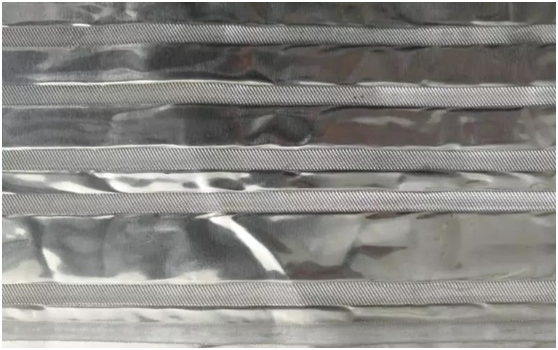

Lithium battery aluminum foil and pure aluminum tab welding Lithium batteries have been widely used in various electronic devices, but a major technical problem that hinders the development of lithium batteries is the problem of single-layer aluminum foil and pure aluminum tab welding of lithium batteries. A major part of the lithium battery production process is the use of an ultrasonic metal wel...

Solar panel welding: Laser Welding VS Ultrasonic Metal Welding First round: Product aesthetics Laser welding uses a high-energy laser to melt the weld metal to create a joint. In the solar heat absorbing plate welding, welding is performed in the form of a solder joint with a spacing of 3-5 mm. Laser welding does not require pressurization on the workpiece, the overall deformation is small, and th...

Battery protection board sampling line welding Due to fluctuations in the actual production process, even if the cells used in the same battery pack are consistently grouped, the difference between the individual cells is still objective. The power battery pack is large in size, and the environment in which the batteries are used in different positions is also different. After the individual cells...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp