Ultrasonic In the Road of Packaging 1 From the time thermoplastic films were first developed, they have made heat sealing a mainstay for packaging designers. It has been adapted widely for sealing everything from thin-wall food and snack bags to clamshell packages for hardware, electronics, and many other applications. But as heat-sealing technology has matured and packaging materials have ev...

What materials are mainly welded by ultrasonic metal welding machine? In theory, the ultrasonic metal welding machine is mainly applied to copper, aluminum, tin, nickel, gold, silver, molybdenum, stainless steel and other non-ferrous metal materials such as thin plates, thin rods, wires, sheets, belts and other materials for instant welding, the total thickness can be Up to 2-4mm . However,...

Ultrasonic wire harness welding machine welding action The ultrasonic wire harness welding machine tool is mainly composed of four parts: welding head, anvil connecting block, anvil top block and polymerization module. When welding, the wires are arranged vertically and tightly attached to the anvil connection block. After the foot switch, the polymerization module moves toward the anvil top block...

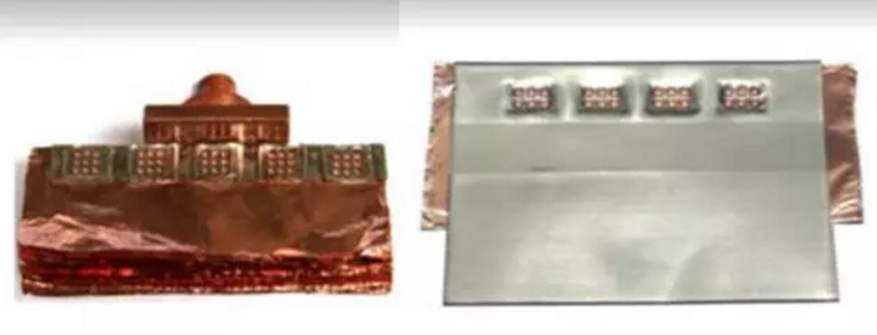

Ultrasonic welding of lithium-ion battery Ultrasonic welding of lithium-ion battery ear is mainly divided into single-point and multi-point welding. Another important application is ultrasonic welding of automatic pole piece welding machine and automatic winding machine. For lithium ion electric construction, the positive and negative single layer copper and aluminum foils are welded wi...

Ultrasonic Welding Machine in Copper Foil and Copper Belt Principle: The high-frequency vibration wave is transmitted to the two metal surfaces to be welded, and under pressure, the metal surfaces are rubbed against each other to form a fusion between the molecular layers. The advantages are fast, energy saving, high fusion strength, good electrical conductivity, good thermal conductivity, no spar...

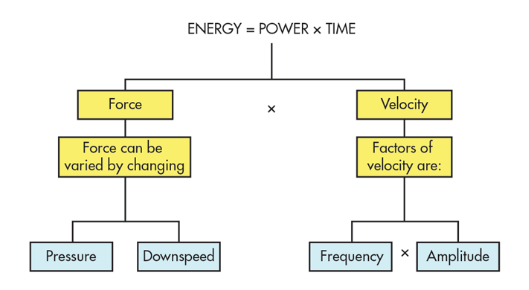

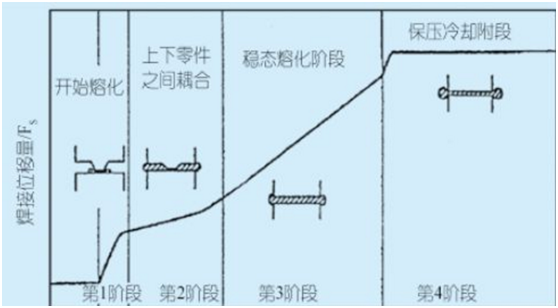

Ultrasonic plastic welding analysis Principle: Ultrasonic mechanical vibration (frequency of 10-70 kHz, amplitude 1-250 μm) is applied to plastic parts to produce local heating under pressure (heat is due to the combined effect of surface and intermolecular friction) and melting Form a weld. As shown, the ultrasonic welding process is divided into four stages. Stage 1: The horn is in contact with ...

Ultrasonic metal welding machine Ultrasonic metal welding is a special method of connecting the same metal or dissimilar metals by using the mechanical vibration energy of ultrasonic frequency. When the metal is ultrasonically welded, neither the current is supplied to the workpiece nor the high temperature heat source is applied to the workpiece, but the mechanical energy is converted into intern...

Ultrasonic large square wire harness welding Ultrasonic welding of automobile wiring harnesses is to weld a multi-strand or single-strand electric wire into a wire knot by an ultrasonic welding process. The advantages are: good electrical conductivity after welding, very low or nearly zero resistivity; short welding time, no need for any flux, gas, solder. But at the same time, automotive w...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp