Ultrasonic automotive wire harness welding machine

Ultrasonic automotive wire harness welding machine

The equipment parameters of

the 3000W ultrasonic wire harness welding machine are as follows:

HSW2030 basic parameters

Working Frequency:20KHz

Power capacity:3000w

Working air pressure: 0.1-0.6 mpa

Working voltage:220V /50Hz

Welder size:520*200*320mm

Welder weight:30KG

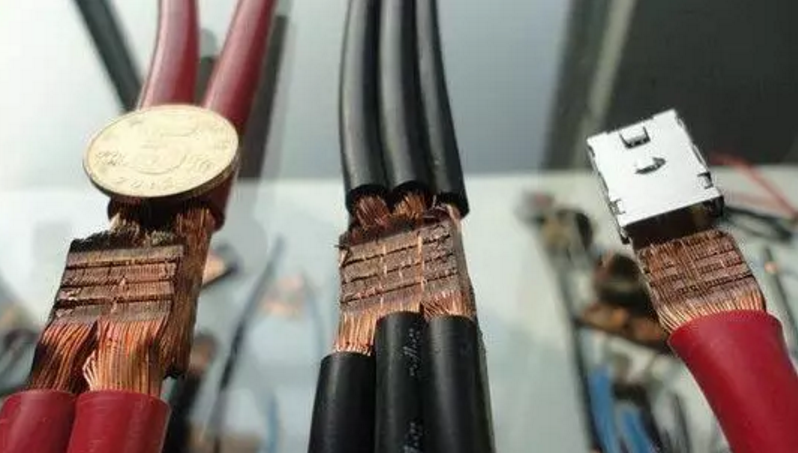

Max welding section:25 mm²

Ultrasonic wire harness welding machine advantages:

As more and more automotive

wire harness welding manufacturers are changed from the old process soldering

to the applicable, the advantages and resistance ratio, the die life is long,

and the electrical conductivity after welding is close to zero resistance,

which is especially suitable for various motor coil taps. The wire is welded

and welded, without any solder, and the fuse is directly welded. By using the

principle of ultrasonic welding, the welding enamel wire can be directly welded

without having to remove the surface insulating varnish in advance without any

solder or auxiliary materials.

The ultrasonic welding

portion has a better compactness and is less likely to form voids.

Ultrasonic welding has a

very low or nearly zero resistivity and is more conductive and improves

durability.

Ultrasonic welding points do

not generate heat accumulation, resulting in local temperature rise, resulting

in quality hazards such as burning of metal workpieces.

Ultrasonic welding is rarely

affected by external factors such as moisture, dust, oil and gas, etc., and it

is not easy to cause rust and oxidation of metal parts, resulting in

deterioration of electrical conductivity and signal transmission performance.

Ultrasonic welding for metal

workpieces, after long-term use, will not cause deterioration of electrical

conductivity due to corrosion and oxidation of copper wire inside the solder

joints, resulting in functional failure.

Ultrasonic welding minimizes

the temperature effect of the material (the temperature of the weld zone does

not exceed 50% of the absolute melting temperature of the weld metal), so that

it does not change the metal structure, so it is suitable for welding

applications in the electronics field.

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp