Automation processes continuously are looking for faster cycle times, tighter tolerances of the process and increased reliability. Pre-loaded ultrasonic welding units are another step to push the limits even further. Depending on the methods of automation for mass production, flexible production of components or a combination of multiple functions, different technologies and approaches can be sele...

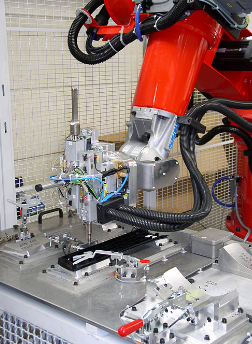

The effect of shrinking high-volume products and growing multiple versions of lower-volume products, especially in the automotive industry, have forced manufacturers to look for more flexible assembly solutions. Today’s requirements include maximizing flexibility and floor space and minimizing tool change setup time. The latest developments are flexible ultrasonic welding cells incorporating robot...

Amplitude: the peak-to-peak excursion of the face of a horn or booster. Booster: a mechanical transformer used to increase or decrease the amplitude of the horn. Far field weld: refers to a weld where the distance between the contact surface of the horn and the weld joint is more than 1/4 inch. Ultrasonic energy is transmitted through the upper portion of the part to the joint surface. Filler: an ...

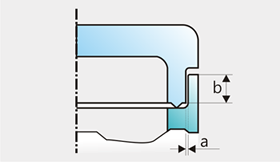

Ultrasonic welding design principles 1. Basic investigation of design In order to achieve good welding results, the factors that must be examined are as follows: Strong joint requirements Whether full-tight welding is required Whether to allow overflow cloth Investigate the plasticity of resin plastics. Which materials can meet the design requirements of the product and meet the basic condi...

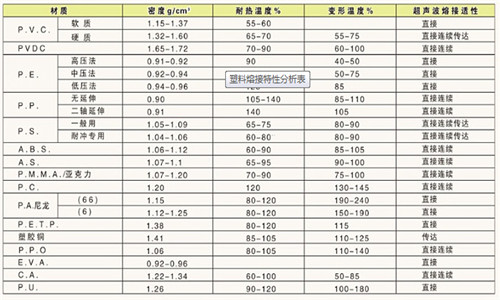

Common misunderstanding of ultrasonic welding 1. Mistaken material of the workpiece Ultrasonic welding is required for the material of the welded workpiece. Not all materials can be welded. Some people think that any material can be welded. This is a big misunderstanding. Some materials can be welded well, some can be welded, and some are Not fused. The melting point between the same materi...

Ultrasonic application involved the assembly of daytime running lights. A clear plastic lens had to be welded to a plastic body with a hermetic seal. The complex 3D shape and class A surface were a challenge to weld. The customer also needed a cost-efficient system that could accommodate many variants for various car models. To solve the problem, technician developed a composite sonotrode separate...

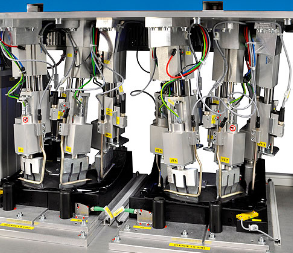

One more ultrasonic application involved bonding pressure-balancing membranes to pump housings. The housings are made of glass-fiber-reinforced polyphenylene sulfide (PPS). The membranes are made of polyester or polycarbonate. The customer wanted to replace expensive precut single membranes with less costly membrane tape. This was a demanding application, because three consecutive ultrasonic proce...

In one application, ultrasonic was tasked with welding aluminum-coated insulation panels for the engine compartment. The material combination was a killer: Aluminum-coated polyurethane (PU) acoustic mats had to be bonded to glass-fiber reinforced polypropylene (PP) panels. If that wasn’t enough of a challenge, six different parts had to be welded. This application represented a real challenge for ...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp