Ultrasonic Bonding Ultrasonic bonding assembles two or more layers of materials by passing them between a vibrating horn and a rotary drum (often referred to as ananvil). The rotary drum is usually made from hardened steel and has a pattern of raised areas machined into it. The high frequency mechanical motion of the vibrating horn and the compressive force between the horn and the ro...

Fabrics - Woven Construction Formed by the regular interleaving of filaments or yarns, in two directions perpendicular to one another Factors Influencing Weldability Thread density, tightness of weave and uniformity of material thickness. Weld strength may vary due to the perpendicular orientation of filaments or yarns. Fabrics - Nonwovens Construction Formed by ...

Fabric & film processing is the bonding, slitting, or sealing of fabrics and films containing thermoplastic material(s). Typical thermoplastic materials found in fabrics and films include acrylics, nylon, polyester, polyethylene, polypropylene, polyvinylchloride, and urethane. Products from the textile, apparel, nonwovens, packaging, medical and automotive industries all benefit from th...

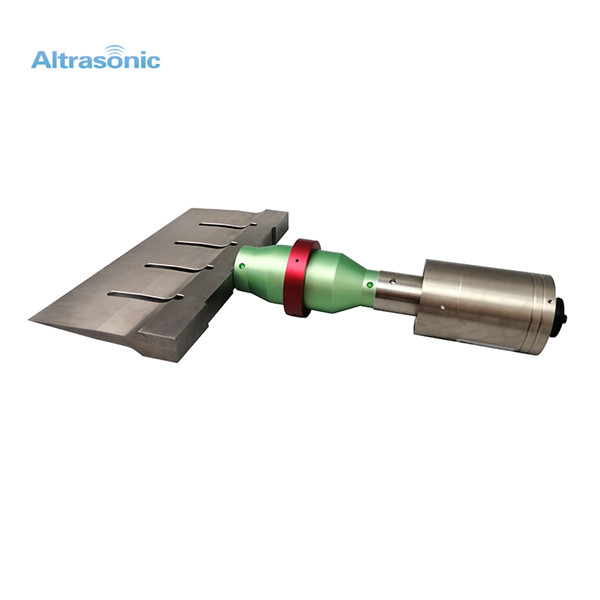

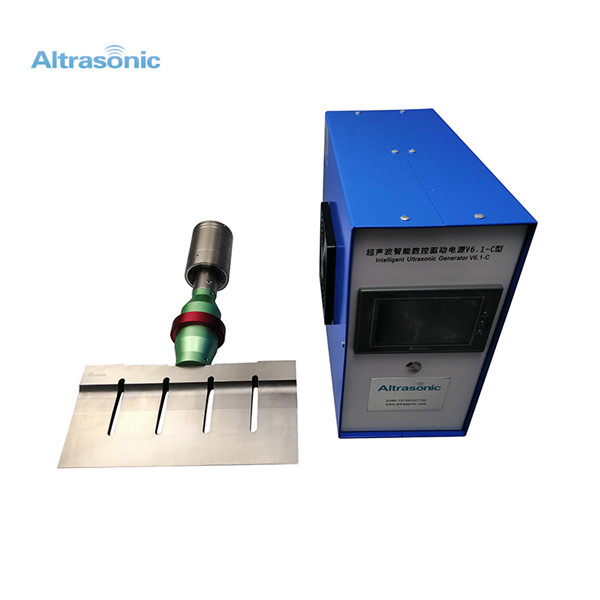

Ultrasonic food processing involves a vibrating knife (guillotine) producing a nearly frictionless surface to which food products do not stick nor deform. The surface cleanly cuts or slits products including fillers such as nuts, raisins, dried fruit or chocolate morsels without displacement or ploughing. Ultrasonic cutting is used by many of the world’s largest and most prestigious food pr...

What are the advantages of ultrasonic food processing? 1. Cleaner, repeatable and more consistent slits and cuts 2. Substantially reduced down time for clean up 3. Outstanding cut aesthetics for multi-layered and delicate products (cakes, sandwiches, baked goods, layered chees and pate products). 4. Wider cutting temperature range 5. Cuts cleanly through various densities and consist...

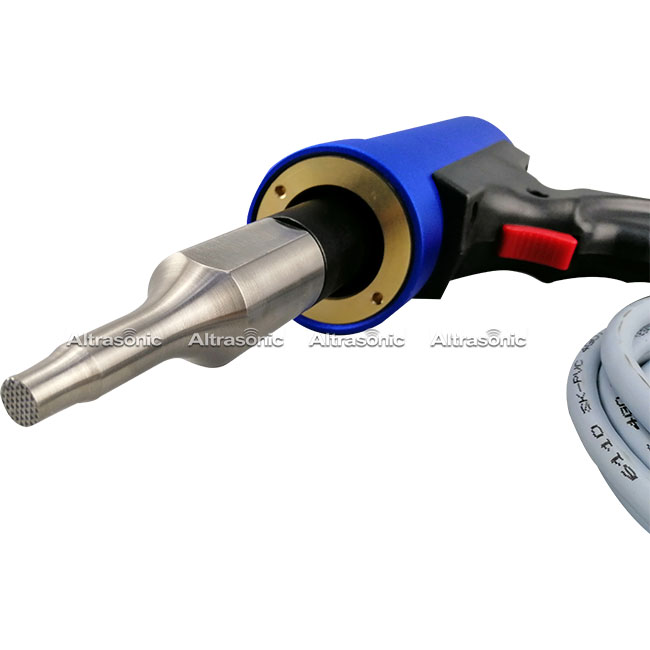

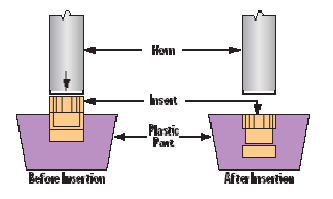

INSERTING Threaded inserts, grub screws or other parts can be ultrasonically embedded in thermoplastics. STAKING Melting and forming of a plastic stud to retain or lock another material, often dissimilar, in place. SPOT WELDING Used for joining two thermoplastic parts with no pre-formed hole or energy director. This technique is particularly suited to large parts...

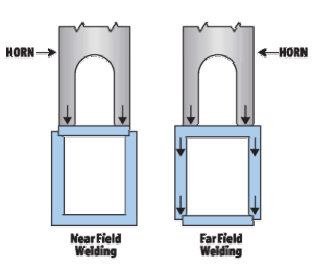

In Ultrasonic welding, high frequency sound energy is used to bring the joining surfaces of two thermoplastic parts to a molten state where they can be permanently welded together. 1. The horn, under pressure from the assembly stand, contacts one of the two mated plastic parts. 2. Vibrational energy from the horn causes the contacted plastic part to vibrate against its mate. 3. The mechanic...

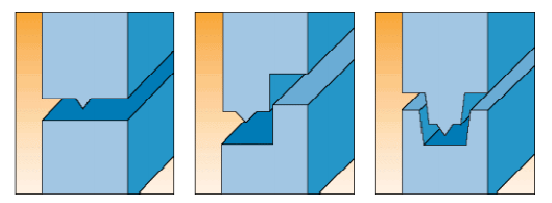

Ultrasonic Joint Designs The basic requirement of any ultrasonic joint design is a small, uniform initial contact area.The design varies with each application and depends on factors such as type of plastic resin to be bonded,part geometry and requirements of the weld. Energy Director Normally a triangular section on the joint that serves to concentrate ultrasonic...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp