Ultrasonic Joint Designs

Ultrasonic Joint Designs

The basic requirement of any ultrasonic joint design is a small, uniform initial contact area.The design varies with each application and depends on factors such as type of plastic resin to be bonded,part geometry and requirements of the weld.

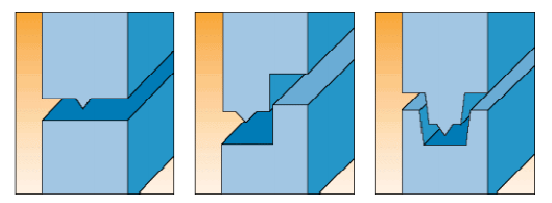

Energy Director

Normally a triangular section on the joint that serves to concentrate ultrasonic energy and rapidly initiates melting of the joining surfaces.

Common joints, which incorporate the use of an energy director, include: butt joints, step joints, and tongue and groove joints.

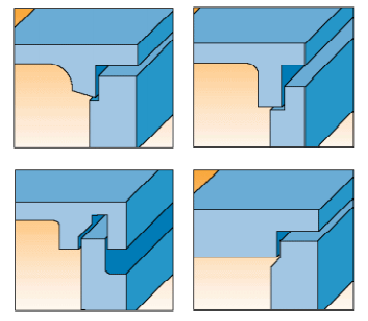

Shear Joints

This type of joint is preferred for parts that require a hermetic

seal or for plastics that change rapidly from a solid to molten

state over a very narrow temperature range.

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp