What is Ultrasonic Spot Welding? It is a process where materials are joined at certain points with no specific joint designed on its interface. It is used in micro-joining of metal or plastic products to multiple parts, such as metal sheets of complex forms. This is also used in soldering, metal welding, hermetic sealing, and thermoplastic joining. This technology was integrated into the ma...

Ultrasound has always been a part of mother nature’s solutions. Bats use it in particular to orient themselves and to fly. By emitting brief ultrasound pulses of less than 1/1000 s duration at a frequency of 50,000 Hertz, they can locate obstacles, but also find the insects on which they feed. Dolphins and blue whales are also able to navigate using acoustic signals. They use a frequency of...

Ultrasonic welding has applications in many fields including the thermoplastics industry. So how does it work? Ultrasound is a mechanical vibration similar to that produced by musical instruments. These vibrations are called ultrasound because they are at a frequency above than the hearing capacity of the human ear (greater than 16 kHz). In an acoustic assembly, these pressure waves are pro...

Ultrasonic welding Assembly by energy applicator. Mainly reserved for amorphous thermoplastics. Ultrasound welding is done very quickly (less than 1 second), without adding material. Ultrasonic spot welding Ultrasound spot welding is particularly recommended for thermoformed parts without an assembly profile, or for parts whose geometry and actual conditions exclude the possibility o...

high efficiency large amplitude low heat stable output unaffected by variations in load competitive pricing fast delivery Typical Applications of Piezo Ultrasonic Transducers Piezo ultrasonic transducers are used in a wide range of applications. In both commercial and industrial environments, these devices allow ultrasonic cleaning apparatus to work effectively — even in the most demanding ...

Seldom will the ceramic component of a composite transducer have adequate tensile strength to withstand the high mechanical stress associated with the power demands for ultrasonic cleaning applications. The tensile strength of the ceramic elements can be supplemented by mechanically pre-stressing the elements along the direction of polarization. Pre-stress is introduced by incorporating a s...

As is true in many other applications for piezo¬electric materials, an assembly of multiple ceramic elements offers considerable performance and production advantages in ultrasonic cleaning transducers, relative to a single ceramic element. In order to provide the most efficient operation, simplify manufacturing, and reduce costs, more complex transducers intended for ultrasonic power appli...

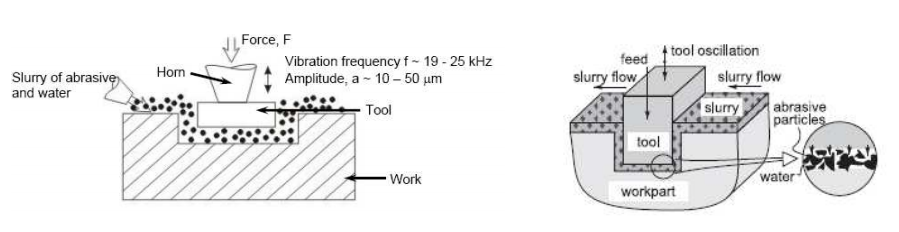

The vibration amplitude curve is shown in the following figure. There is no vibration at node, but the largest stress appears at these points. The machining efficiency is determined by the following factors, 1) Vibrational amplitude of the tool 2) Working pressure to the work piece 3) Condition of abrasive fed to the work piece Too large working pressure a well as too small pressure ...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp