There is a range of applications of ultrasonic welding. These include (but are not limited to) mounting of lenses and windows in housings, plastic-to-plastic joints, and placement of mechanical clamps, studs, and pierced inserts into molded components for plastic injection. Is your item a suitable ultrasonic welding candidate? If it is, then using this welding method has many benefits, as o...

Before today, were you aware that high-frequency sounds can be utilized to bind together different materials? You most probably weren’t. Here is some information to add to your knowledge: Ultrasonic welding technology is used to combine items from a range of industries, including from the automotive, sports footwear, and medical equipment industries. So, what is ultrasonic welding? I...

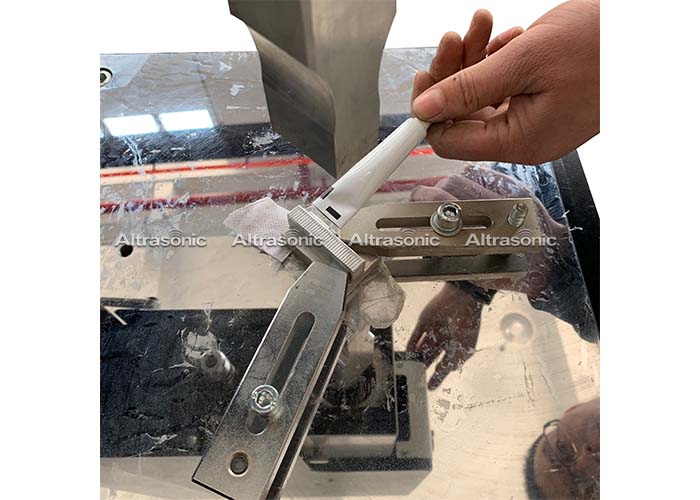

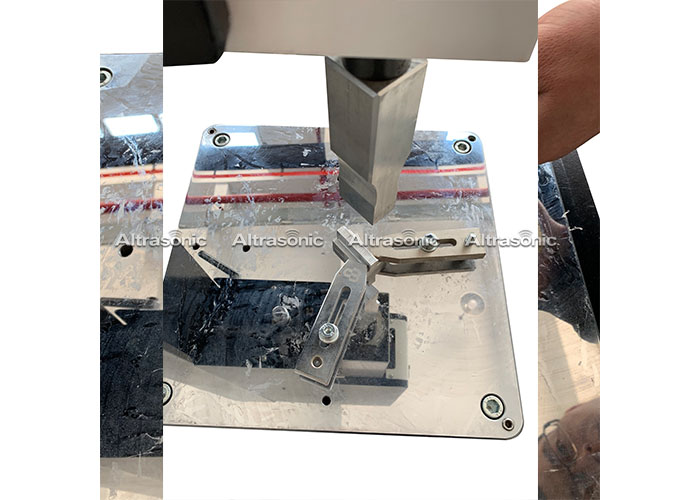

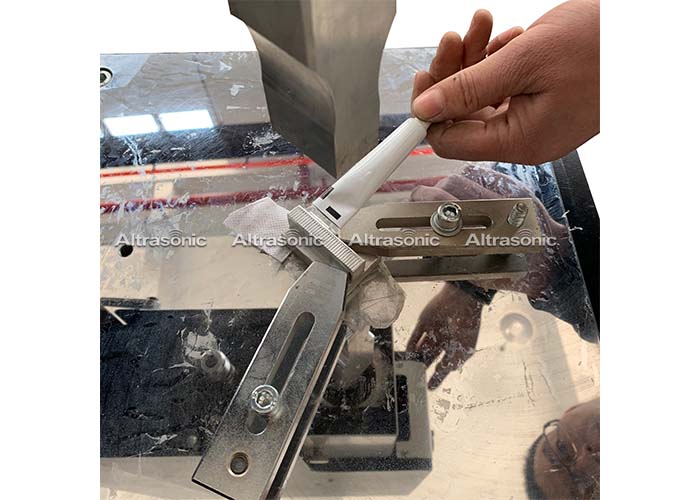

In the plastics processing industry, the ultrasonic joining technology has been utilized in a wide range of applications as a joining tool for specialized thermoplastic materials. Ultrasonic welding has a fast and easy operation. This welding process can be performed in the following six simple steps. Step 1—Nesting the Parts Together The thermoplastic components that need to be erec...

Often people mistake vibration welding for ultrasonic welding and vice versa. This is because both methods utilize vibrational force to weld plastic assemblies. However, the reality is that both these welding techniques are very different from each other. The vibration welding method pulsates in a linear side-to-side movement with one part proportional to another. The friction betwee...

Knowing the different parts involved in the ultrasonic welding process is extremely important to perform this welding technique efficiently. Ultrasonic welding machines are designed to transform electricity efficiently to mechanical vibrations. They are equipped with a microprocessor that reads the conditions and then controls the heating accordingly. The following are some of the component...

The very first thing that comes to mind when you think about joining two or more components together is a common screw or a mixture of bolts and nuts. Although this is easy to perform, it can add costs and complexity to a manufacturing process that might not be necessary. A simplified solution is provided by ultrasonic welding which minimizes cost and complexity while fulfilling the assembl...

Ultrasonic welding is widely used in the electronics industry to weld together wiring in delicate circuits and on microcircuits. It is also used in the automotive industry, medical industry, and packaging industry, often to weld dissimilar materials or plastics. The major advantages in ultrasonic welding are that it is a fast welding speed technique that also exhibits high energy efficiency...

Spot welding is a type of resistance welding used to weld metal sheets together. Also known as resistance spot welding, it applies external force at singular points or spots, to press and join the surface area. This older form of welding metals to sheets is usually done by passing an electric current without a filler. Resistance spot welding is very important in the manufacturing ind...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp