Ultrasonic metal welding is to transmit tens of thousands of high-frequency vibration waves per second to the surface of two metal workpieces to be welded, and then apply a certain pressure to make the metal surfaces rub against each other to form a fusion between the molecular layers, thusing achiving the purpose of welding. Our ultrasonic metal welding machine uses frequency automatic tra...

The ultrasonic horn is an important component of the ultrasonic vibration system. The main function is to amplify the mass displacement or velocity of the mechanical vibration and concentrate the ultrasonic energy on a small area. The main function of the ultrasonic horn is to change the amplitude of the transducer (generally increase), increase the vibration ratio, improve the efficiency, ...

Ultrasonic food cutters are a type of equipment that uses ultrasonic energy for cutting. It is characterized by cutting without the cutting edge in the traditional sense. We offer complete professional equipment and components for ultrasonic food cutting. Compared with traditional cutting machines, ultrasonic food cutters have more sanitary cutting, shorter downtime, better cost-effectivene...

Ultrasonic extraction equipment is equipped with the ultrasonic device invented by our company. Under normal and low temperature conditions, the extraction time is shortened to 20~40 minutes, ensuring continuous operation and dynamic countercurrent extraction, improving production efficiency, reducing solvent dosage and reducing the extraction temperature. It ensures the quality of the prod...

Ultrasonic welding transducers generate high-frequency vibrations of tens of thousands of times per second through the transducer at the vibrating head, generating local high temperatures, and melting the plastics in the weld zone for welding purposes. The ultrasonic welding transducer generally adopts a bolt-clamped longitudinal array structure, which is connected with the fixing fixture a...

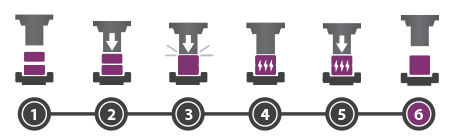

What is ultrasonic package sealing? Ultrasonic package sealing occurs when high frequency (ultrasonic) mechanical energy is transferred into two or more layers of thermoplastic materials. A strong, reliable molecular bond is formed between the layers. Nearly all packaging materials and laminates, with a thermoplastic sealing layer or coating, are suitable for the ultrasonic sealing (...

Processing Techniques-Ultrasonic Packaging Ultrasonic Bonding Ultrasonic bonding assembles two or more layers of materials by passing them between a vibrating horn and a rotary drum (often referred to as ananvil). The rotary drum is usually made from hardened steel and has a pattern of raised areas machined into it. The high frequency mechanical motion of the vibrating h...

Ultrasonic packaging-Advantages of Ultrasonic Sealing 1. Short Cycle Times = Increased Though-put 2. Possibility to use the sealing process to monitor quality control 3. Low energy consumption 4. Clean and simple to maintain 5. Ultrasonics can seal through remnants like drops of liquid, or small amounts of powder or fibrous material that may be in the seal area 6. Ultrasonic process ...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp