Many different types of materials have been used to build fixtures for ultrasonic assembly including plastics, stainless steel, tool steel, aluminum, cork, poured urethane and silicone rubber. All of these can play a role depending upon customer’s needs, but the most common fixtures include aluminum, steel and poured urethane. Poured urethane fixtures are frequently used for supporting rigi...

The use of CAD/CAM technology has greatly improved the manufacturing of contoured fixtures to support the part during ultrasonic assembly. Exact mirror replicas of the part can be created to provide excellent support to the part. Due to complex contours seen on many parts, it is recommended that the horn and fixture be purchased as a set, so proper alignment is achieved between the two. The...

The latest advances in ultrasonic welding for medical devices are driven by the need to assemble plastic parts that tend to be smaller and lighter in weight, thinner-walled, and often more contoured than in the past. A growing number of these parts also contain embedded electronics and sensors that require special care in the ultrasonic welding process. Meeting the medical device ind...

Ultrasonic Package Welding This Ultrasonic Package Welding machine is suitable for the packaging of plastic products of electronic products, with good sealing performance and high production efficiency. The machine adopts high quality piezoelectric ceramic transducer, which outputs strong and stable titanium alloy horn, square column, guide bearing. The adjustable fine adjustment device bot...

The ultrasonic welding generator produced by our company uses a self-excited circuit. When it is working, it can stably track changes in transducer parameters and maximize the performance of the plastic welder transducer. This kind of equipment adopts imported high-power tube, which is resistant to large current impact and increases the stability of the operation of the ultrasonic generator...

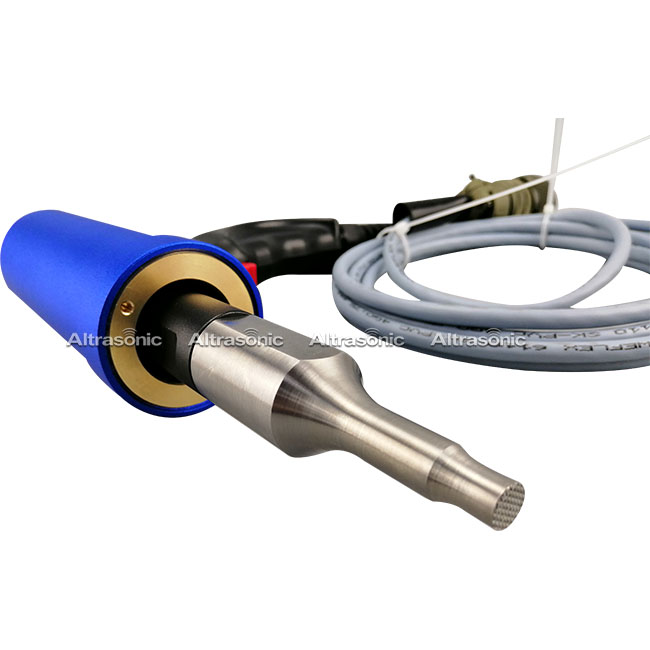

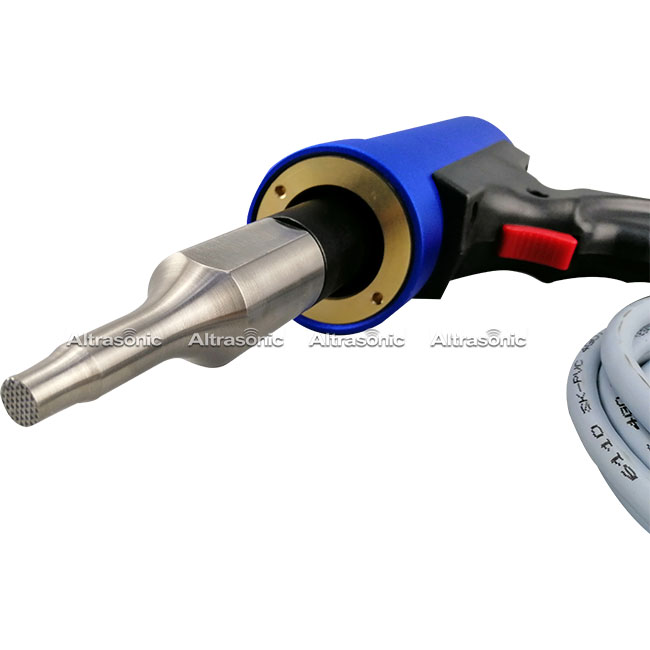

Ultrasonic rubber cutting machine is a special application of ultrasonic cutting machine. It is a kind of equipment that uses ultrasonic energy to cut and process. Its biggest feature is that cutting does not use cutting edge. Ultrasonic cutting uses the energy of an ultrasonic transducer to melt the localized heat of the material to be cut, thereby achieving the purpose of cutting the mate...

Welding principle of ultrasonic paper cup welding machine: When ultrasonic waves act on the thermoplastic plastic contact surface, high frequency vibrations of tens of thousands of times per second are generated. When it reaches a high-frequency vibration of a certain amplitude, the ultrasonic energy is transmitted to the weld zone by the upper weldment, and a local high temperature is gene...

The basic configuration of ultrasonic non-woven welding machine includes new intelligent ultrasonic generator, bottom mold with synchronous rotation function, two-way motor speed control system, manual (or optional pneumatic) pattern lifting system, multi-functional pattern bracket and level Fine-tuning mechanism and double-tube rack heavy platen. Ultrasonic non-woven fabric welding machine...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp