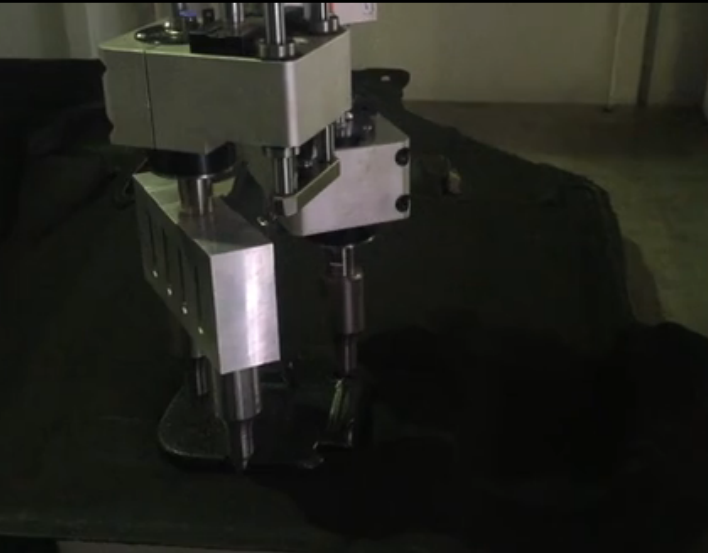

Car trunk spare tire cover sound insulation cotton ultrasonic spot welder can also be called car trunk spare tire partition sound-absorbing carpet ultrasonic welding machine, is to use ultrasonic technology to weld the sound insulation cotton on the spare tire cover, according to the customer's output and beat A suitable machine is recommended. If the amount is small, it can be welded by a ...

In modern vehicles, whether it is exterior decorative parts (such as bumpers, fenders, wheel covers, deflectors, etc.), interior decorative parts (such as instrument panels, door inner panels, sub-dashboards, glove compartment covers, seats) Chairs, rear guards, etc.), or functional and structural parts (fuel tank, radiator water chamber, air filter cover, fan blades, etc.), the shadow of plastic ...

The automobile ultrasonic sound-absorbing cotton and sound-absorbing cotton felt ultrasonic welding technology is widely used in the automobile industry. There are automobile trunk spare tire cover sound-insulating cotton, automobile center console sound-proof cotton, automobile engine cover noise-proof cotton, automobile trunk sound-proof cotton, Ultrasonic welding of automobile wheel cove...

Ultrasonic welding auto parts process There are more and more plastic parts and interior parts in auto parts, which requires plastic welding technology. Because of the complexity of plastic materials and the non-standard of auto parts, it is decided that automotive plastic parts require a variety of plastic welding processes, in which ultrasonic welding, hot plate welding, and laser welding...

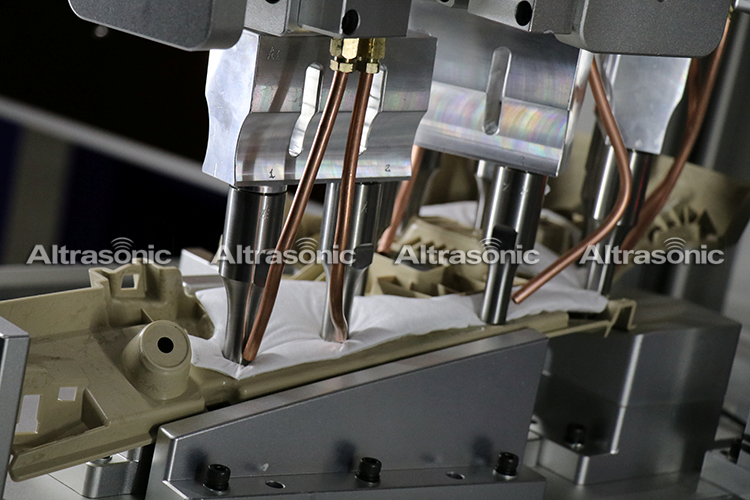

Ultrasonic spot welding effect of automobile engine cover Different car engine guard board soundproof cotton need to weld different points, but the process is the same. Each ultrasonic welding spot is soldable, replacing the traditional bonding process. The automobile engine cover noise insulation cotton ultrasonic welding head is made of 7075 aviation aluminum material. When the sound insulation ...

The welding strength meets the customer's requirements. Two points can be welded by ultrasonic sub - mother, there is a single point ultrasonic welding point. The trajectory of the ultrasonic horn sliding can be controlled by plc. Adopt ultrasonic import system. Automobile launching under the guard plate foam and felt ultrasonic welding machine features 1. Using plc controller to accurately...

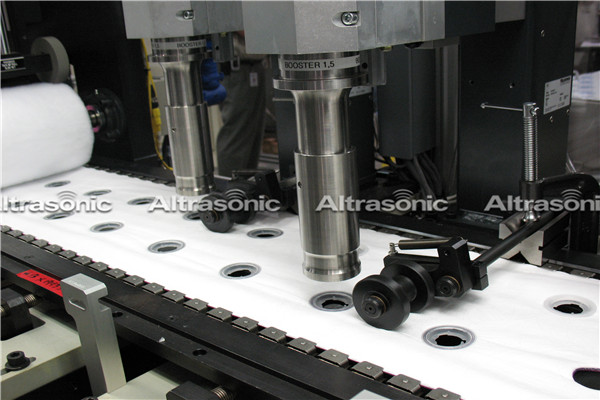

Automobile wheel cover sound insulation cotton ultrasonic spot welding sample The automobile wheel cover sound insulation cotton is welded firmly at all points to meet the customer's pulling requirements. Car wheel cover sound insulation cotton is relatively thick, using imported ultrasonic welding system. Features of ultrasonic welding machine for multi-head edge of automobile wheel hub so...

Car luggage insulation cotton ultrasonic welding sample Features of auto trunk carpet sound-absorbing cotton multi-head ultrasonic pressing equipment 1. Use safety grating, alarm, emergency stop switch and other safety devices; 2. Each ultrasonic welding head is controlled separately, which can control the moving direction of welding head and separate blowing device; 3. Adopt four-pillar mold chan...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp