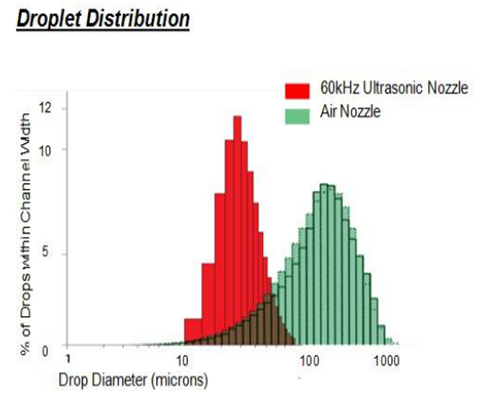

Compared with traditional two-fluid spraying, ultrasonic spraying has the advantages of high coating uniformity, high raw material utilization, high coating thickness control accuracy, thinner coating thickness, less splash, no clogging of nozzles, and low maintenance costs. Compared with vacuum evaporation, CVD and other coating processes, ultrasonic spraying is a more economical thin film...

In ultrasonic turning, the high-frequency electrical oscillations generated by the generator (the frequency is generally 16 to 25 kHz, and the welding frequency can be higher) are applied to the ultrasonic transducer (see picture) to convert the high-frequency electrical oscillations into ultrasonic vibrations. Ultrasonic vibration uses a horn to amplify the amplitude (double amplitude is 20 to 80...

UM effectively machines precise features in hard, brittle materials such as glass, engineered ceramics, CVD SiC, quartz, single crystal materials, PCD, ferrite, graphite, glassy carbon, composites and piezoceramics. A nearly limitless number of feature shapes-including round, square and odd-shaped thru-holes and cavities of varying depths, as well as OD-ID features-can be machined with high qualit...

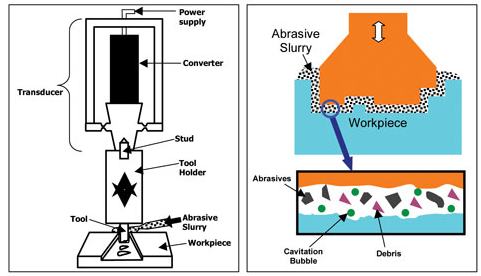

In the UM process, a low-frequency electrical signal is applied to a transducer, which converts the electrical energy into high-frequency (~20 KHz) mechanical vibration (see Figure 2). This mechanical energy is transmitted to a horn and tool assembly and results in a unidirectional vibration of the tool at the ultrasonic frequency with a known amplitude. The standard amplitude of vibration ...

Ultrasonic machining can be used to generate a wide range of intricate features in advanced materials. Figure 1. Square, round and odd-shaped thru-cuts in alumina. Engineered ceramic materials exhibit a host of very attractive properties for today’s scientists, design engineers and R&D engineers. Properties of interest include high hardness, high thermal resistance, chemical inertness, tailore...

On December 12, 2019, Altrasonic hosted general managers from India. We discussed the application of ultrasonic machines, focusing on the introduction of ultrasonic sealing & cutting fabric, cavitation equipment, ultrasonic metal welding wire, ultrasonic machining. Our engineers performed cutting tests on client’s fabric, and demonstrated the use of various ultrasonic machines. Clients also ex...

In recent years, due to its excellent quality, high cost performance and perfect after-sales service our company---- Hangzhou Altrasonic Technology co., ltd. attracted customers from all over the world. Good reputation and market recognition, also attracted many foreign customers to visit. On December 11th, the Russian customer as well as an expert in German ultrasonic technology came to visit our...

This month, a customer came to our company to discuss the technology of ultrasonic products. Customers are interested in our ultrasonic rotery seal. Since the schedule of the client is very tight, we held a meeting with the client in the hotel. Our sales manager Hogo and the technical team worked with the customer on the technical discussions. The theme of this meeting is to use ultrasonic sealing...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp