Application of ultrasonic welding in the automotive industry

Ultrasonic welding auto parts process

There

are more and more plastic parts and interior parts in auto parts, which

requires plastic welding technology. Because of the complexity of plastic

materials and the non-standard of auto parts, it is decided that automotive

plastic parts require a variety of plastic welding processes, in which

ultrasonic welding, hot plate welding, and laser welding are widely used. In

the automotive industry, welding is a key link in the manufacture of automotive

parts and bodywork. It plays a special role in connecting the upper and lower.

At the same time, there are many models of automobile products, complex forming

structures, specialized parts production, standardization, and quality of

automobile manufacturing. The comprehensive requirements of efficiency and cost

have determined that automotive welding processing is a multidisciplinary,

cross-disciplinary and technologically integrated production process. The

quality of plastic welding determines the quality of the entire vehicle!

Application of ultrasonic technology in auto parts

Ultrasonic

plastic welding: taillights, rearview mirrors, buckles, filters, shunts,

plastic case and watch case, air filter cover, fan blades, signs, fuse cover,

airbag bracket, push button switch, bearing retention Frame, front wall

insulation pad, car sun visor, interior pendants, etc.

Ultrasonic plastic spot welding

Automotive

interior parts, PP soundproof cotton, plastic columns, non-woven soundproof

felt, car door panels, electrical components riveting, car dashboard, car logo,

folder positioning, bumper, manual gear sheath, car inner panel, car Felt mats,

car mats, instrument panels, car trim panels, auto parts, etc.

Ultrasonic non-standard welding

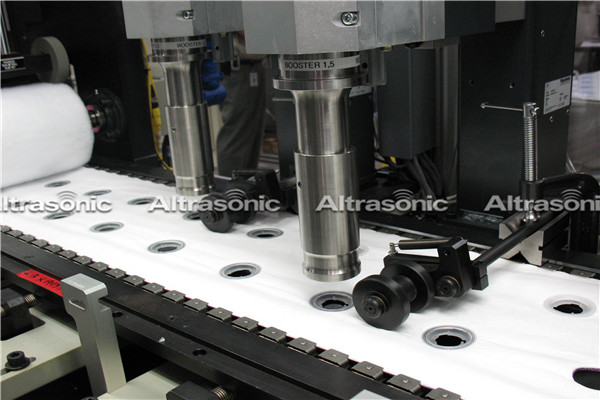

Most

of them are welding large and complex work, using a multi-head design to weld

from different directions. For automotive door panels, car dashboards, car

bumpers, automotive parts riveting, car logos, car profile covers, car rear

partitions, car coat racks, car front covers, car headlights, automotive

interior panels.

Ultrasonic plastic welding technology

Ultrasonic is suitable for welding ABS, acrylic, polycarbonate, nylon, cellulose acetate, etc. Welding of polyethylene and polypropylene has encountered some problems, and usually they require high energy. Regardless of the material, it must be dry because the presence of moisture can weaken the joint strength. Ultrasonic welding is fast (typical welding time is from 015 to 115 s) and is easy to automate, making it ideal for high volume production. Applications for ultrasonic welding in the automotive industry include: instrument panels, motor housings, bearing cages, lampshades, (cab) glove boxes, lenses, filters, valves, air commutators (shunts), airflow detectors, and more.

Non-standard

ultrasonic welding is suitable for welding large and complex workpieces. Since

large and complex workpieces contain welded joints in different directions,

multiple positions need to be welded at the same time. Standard models are not

suitable for special machines, such as automobile dashboards, door panels, and

insurance. Bar and so on. However, non-standard ultrasonic welding equipment

can only produce one large and complex part at a time, and it is not very

common at present.

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp