Emulsifying by Ultrasonic Cavitation A wide range of intermediate and consumer products, such as cosmetics and skin lotions, pharmaceutical ointments, varnishes, paints and lubricants and fuels are based wholly or in part of emulsions. Systems consisting of several ultrasonic processors of up to 16,000 watts each, provide the capacity needed to translate this lab application into an efficient prod...

Application for Ultrasonic Homogenizer The application of ultrasonic homogenizer is as follows: 1. Breaking up of cells, bacteria, viruses, spores, fungi, or tissues 2. Extraction of ingredients 3. Homogenization of substances of all kinds 4. Production of the finest emulsions with minimal droplet size 5. Dissolution of hard-to-dissolve and extremely hard-to-dissolve substances in fluids 6....

The ultrasonic system of the mask machine includes: generator, vibrator (transducer + booster), welding horn, flange, etc. Ultrasonic generator is divided into automatic frequency tracking circuit and manual frequency modulation circuit. Experienced tuning personnel can choose manual frequency modulation generator, which is more stable and less susceptible...

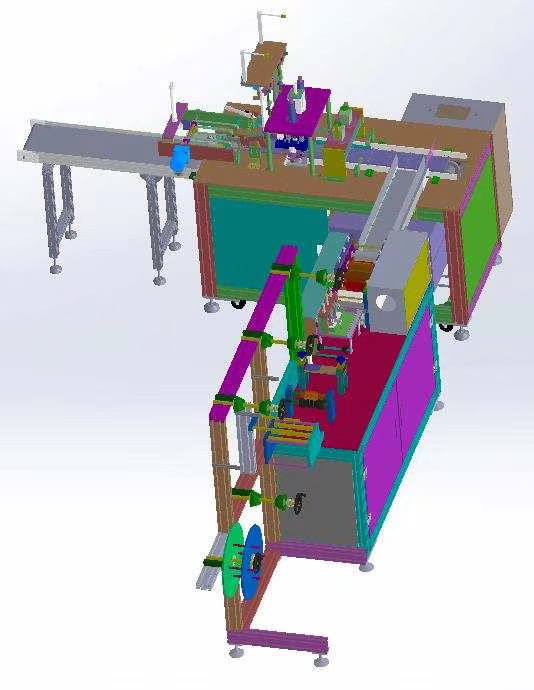

Ultrasound Systems in Non-woven Mask Machine The ultrasonic accessories in the non-woven mask machine are composed of an ultrasonic generator (ultrasonic power supply), an ultrasonic transducer, an ultrasonic welding horn, and a flange. It is the core welding part of the mask machine, which is used for welding around the mask, the bridge of the nose, and ear line Welding; One-to-one, one-to-two fu...

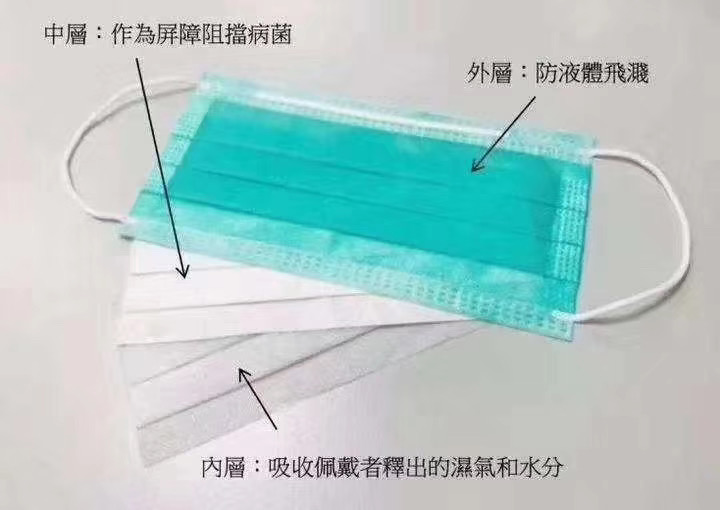

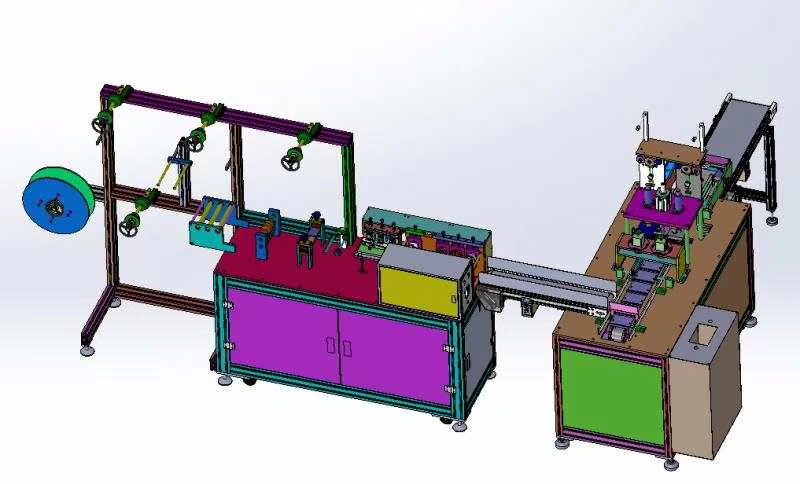

Ultrasound System in Plane Mask Machine The flat mask machine produces disposable flat masks as well as the equipment for producing medical masks. The masks produced by this machine are simple in style and easy to wear. The flat masks are produced by using two layers of non-woven fabric and filter paper, and disposable three-layer masks. It is a melt-blown cloth made by adding a layer of filtratio...

Mechanized Production Process of Ultrasonic Mask Making Equipment Common disposable masks on the market are made of non-woven raw materials, which need to be used: 1. PP non-woven fabric, 2. Meltblown cloth, 3. Nose bridge strip, 4. Ear band and other materials. In addition to the above raw materials, production equipment is also needed: 1. Mask masking machine, 2. Mask ear band spot weldin...

Flat mask machine The ultrasonic planar mask machine uses ultrasonic welding. When the mask is moved to the processing position, ultrasonic waves are automatically generated, which form micro-amplitude high-frequency vibration on the earband, which is instantly converted into heat, welding the material to be processed, and finally making the earband Permanently pasting or embedding inside the mask...

The production of mask machines is actually not complicated, starting from slitting non-woven fabrics, to origami machines, ultrasonic welding machines or resistance hot presses, hemming machines, die-cutting or laser forming machines, laser coding machines, disinfection Sterilizers, and finally packers, etc. In fact, there are mature stand-alone equipment or head parts on the market. As long as t...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp