Ultrasonics for Biodiesel Processing Today, biodiesel is primarily produced in batch reactors. Ultrasonic biodiesel processing allows for the continuous inline processing. Ultrasonication can achieve a biodiesel yield in excess of 99%. Ultrasonic reactors reduce the processing time from the conventional 1 to 4 hour batch processing to less than 30 seconds. More important, ultrasonica...

Ultrasonic Disintegration of Cell Structures Ultrasonication is an effective means to break cell structures. This effect can be used for the extraction of intracellular materials, e.g. starch from the cell matrix.Ultrasonication generates alternating high-pressure and low-pressure waves in the exposed liquid. During the low-pressure cycle, the ultrasonic waves create small vacu...

Sonochemical Reaction and Synthesis Sonochemistry is the application of ultrasound to chemical reactions and processes. The mechanism causing sonochemical effects in liquids is the phenomenon of acoustic cavitation. Altrasonic ultrasonic laboratory and industrial devices are used in a wide range of sonochemical processes. Ultrasonic cavitation intensifies and speeds up chemical...

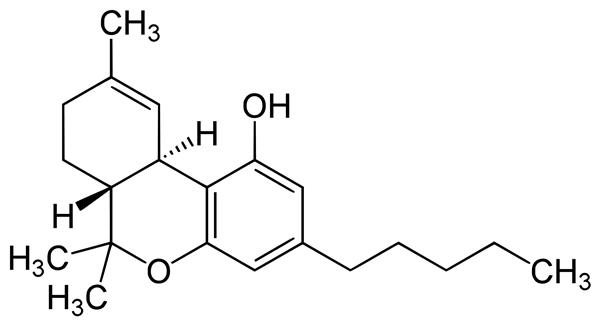

Fast & Simple Ultrasonic Cannabis Extraction 1. To meet the rising demand and to supply cannabinoids of high quality, an efficient and reliable cannabis extraction method is substantial. Ultrasonic extraction is proven to shorten the extraction time and to increase yield considerably. 2. With power ultrasound, cannabis extraction gets faster, more complete and highly efficien...

Ultrasonic Extraction and Preservation The disintegration of cell structures (lysis) by means of ultrasound is used for the extraction of intra-cellular compounds or for the microbial inactivation. Background In microbiology, ultrasound is primarily associated with cell disruption (lysis) or disintegration (Allinger 1975). When sonicating liquids at high intensitie...

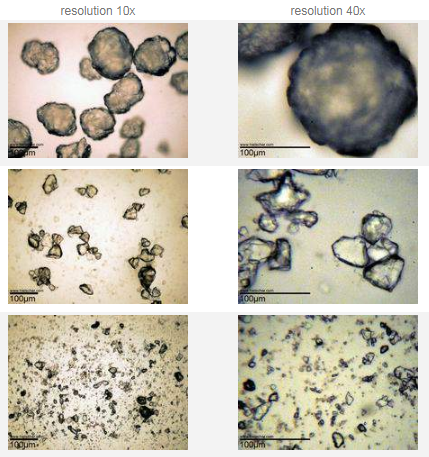

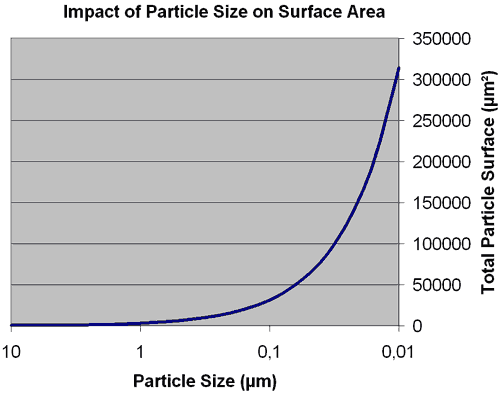

Ultrasonic Wet-Milling and Micro-Grinding Ultrasonication is an efficient means for the wet-milling and micro-grinding of particles. Besides dispersing and deagglomerating, the wet milling is an important application of Hielscher ultrasonic devices. In particular for the manufacturing of superfine-size slurries, ultrasound has many advantages, when compared with common size reduction equipme...

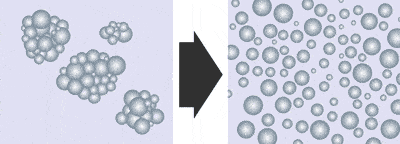

Ultrasonic Dispersing and Deagglomeration The dispersing and deagglomeration of solids into liquids is an important application of ultrasonic devices. Ultrasonic cavitation generates high shear that breaks particle agglomerates into single dispersed particles. The mixing of powders into liquids is a common step in the formulation of various products, such as paint, ink, shampoo, beverages, o...

Ultrasonic Homogenizers Ultrasonic homogenizers are powerful tools to mix and homogenize solid-liquid and liquid-liquid suspensions. Ultrasonic homogenization is a mechanical process to reduce particles in a liquid so that they become uniformly small and evenly distributed. Impact of Ultrasonic Homogenizers When ultrasonic homogeizers are are used for applications such as mixing, dispersing and em...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp