The Definition of Technical Ceramic: Technical ceramic is also referred as precision ceramic and advanced ceramic. Technical ceramic can be classified with applications or the compositions of materials, such as technical ceramic and engineered ceramic, or silicate ceramic and oxide ceramic. Popular types of technical ceramic are alumina, zirconia, SiC and AIN. The differences between...

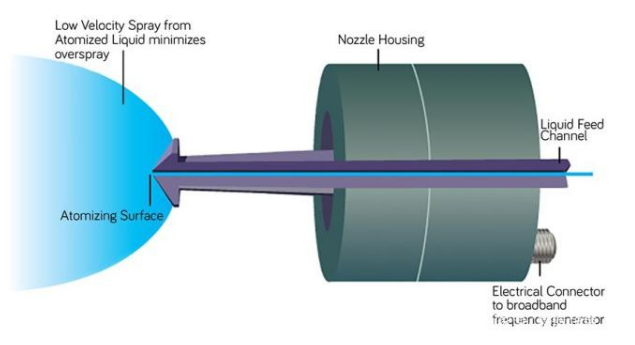

Ultrasonic spraying is a unique spraying technology, which is a spraying method based on ultrasonic atomizing nozzle technology. Compared with traditional pneumatic two-fluid spraying, ultrasonic atomized spraying can achieve better uniformity, thinner coating thickness and higher precision. At the same time, because the ultrasonic spray nozzle can be atomized without the aid of air pressur...

Liquid atomization is a process in which a thin liquid film that is sufficiently disturbed by the surface in the normal direction is separated from the surface and split into small water droplets, such as mist in the gas phase. Liquid atomization plays an important role in industrial processes such as spray drying, coating, spray cooling, liquid fuel and waste incineration and combustion, f...

Ultrasonic atomizing nozzle-The ultrasonic air atomizing nozzle is made of stainless steel as a whole, with precise workmanship and good spraying effect. This is a dust suppression device with aerodynamic auxiliary spray. It belongs to a typical two-fluid atomization series. The principle is: compressed air is used to impact the resonant cavity to generate ultrasonic waves, and the ultrason...

Relevant research believes that ultrasonic atomization is the process of using ultrasonic energy to make liquid form fine droplets in the gas phase. That is, ultrasonic waves are generated on the vibrating liquid surface, and the vibration peak formed by the amplitude separates and breaks the droplets from the surface. As the ultrasonic frequency increases, the atomized droplets become fine...

Some of the many benefits of ultrasonic nozzles: High Transfer Efficiency – Reduces materials usage Non clogging – Able to handle high-solid materials Durability – Titanium construction is resistant to many solvents and abrasion. Highly uniform distribution of droplet sizes – Reduces coating imperfections. Airless spray – Can easily control process and also ideal for vacuum env...

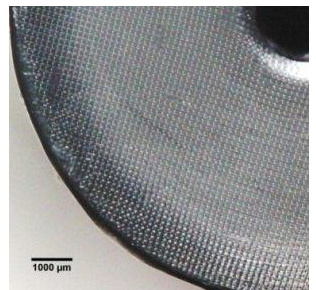

The workpiece is held in a tank of slurry containing abrasive particles, the slurry is injected into the space between a vibrating tool and stationary workpiece. Material is abraded away until a mirror image of the tool is cut into the workpiece. A metal tool is given a high frequency, low amplitude oscillation perpendicular to the workpiece, which transmits a high velocity to fine abrasive...

Ultrasonics for Oil, Gas and Renewable Fuels Oil prices and greenhouse gases as well as the sustainability of fuel sources became a focal point of interest in the oil & gas industry. Hielscher ultrasonic devices are used in research facilities and processing plants for many applications. Ultrasonic devices made by Altrasonic are used for many processes, such as mixing, dis...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp