Rub your hands together rapidly. Notice anything? They warmed up, right? If you take a hammer and pound a metal surface rapidly and repeatedly, you will find that the place where the hammer strikes the metal warms up, too. In both these examples, the heat is due to friction. Now imagine rubbing your hands or pounding that hammer thousands of times per second. The frictional heat generated c...

General description The ultrasonic welding technology for plastics is considered part of the melt welding processes. The process is based on a conversion of friction and vibration energy into heat. Using a welding tool called a sonotrode, the high-frequency vibrations generated by the ultrasonic system, in combination with pressure, are transferred to the parts to be joined, which leads to ...

Ultrasonic welding is a widely recognized and accepted process for joining thermoplastic materials. It offers many advantages, including process reliability and repeatability, lower energy usage than other joining techniques, material savings (because there is no need for consumables, such as glue or mechanical fasteners), and labor savings. But as with any process, there are situati...

The phenomenon referred to as ultrasonic atomization has its roots in late 19th century acoustical physics, notably in the works of the ubiquitous Lord Kelvin. Simply stated, when a liquid film is placed on a smooth surface that is set into vibrating motion such that the direction of vibration is perpendicular to the surface, the liquid absorbs some of the vibrational energy, which i...

The ultrasonic power supply converts 50/60 Hz voltage to high frequency electrical energy. This electrical energy is transmitted to a piezoelectric transducer with the converter, where it is changed to mechanical vibrations. The ultrasonic vibrations are intensified by the probe and focused at the tip where the atomization takes place. Every ultrasonic nozzle operates at a specific r...

Unlike applications in medicine, inspection and parts cleaning where ultrasonic (high frequency sound) waves are applied directly, ultrasonic machining is a metalcutting process that is facilitated by ultrasonic technology. The process, developed by Sauer & Company (Stipshausen, Germany), uses a diamond coated milling, boring or grinding tool, actuated by ultrasonic technology, that can...

Ultrasonic technology machines hard, brittle materials accurately and easily. Ultrasonic machining is an easy-to-use technology that allows a mold manufacturer to machine very hard or brittle materials with flexibility and accuracy. Ultrasonic machining centers can perform both conventional and ultrasonic machining operations. By combining these technologies in one machine, the user ...

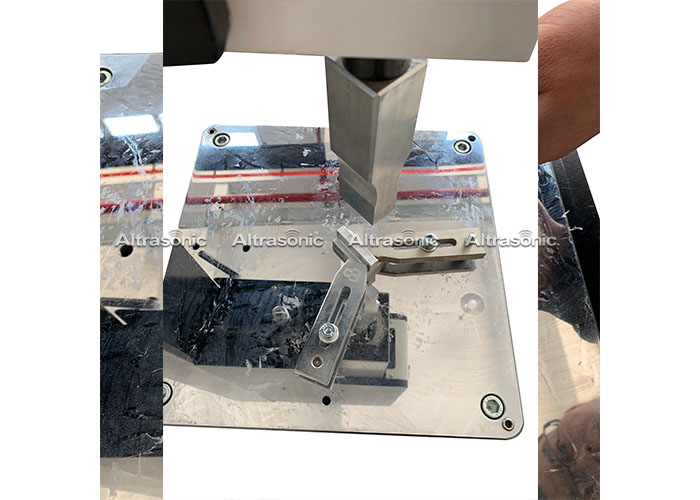

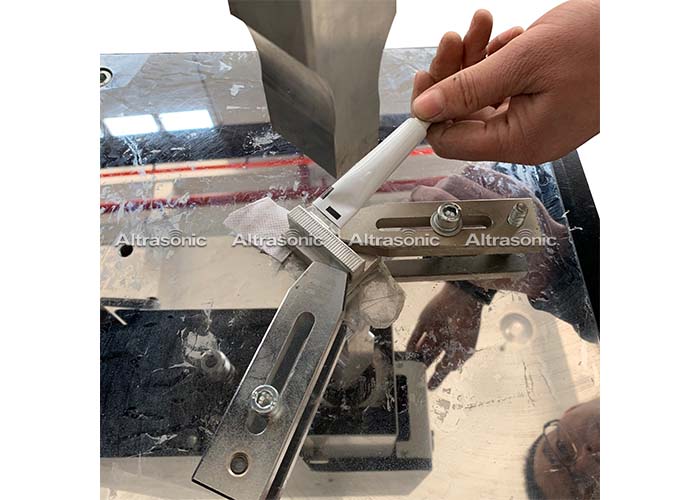

Ultrasonic cutters can smoothly cut difficult-to-cut materials. They are small in size and do not require large installation areas. Special equipment is not required for the installation. They are small enough to be hand-held for many operations. They can also be attached to automated machinery arms. Although they may not be familiar to you, they play an active role in the manufacturing pro...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp