Ultrasonic machining is a machining method developed in recent decades, which makes up for the shortcomings of EDM and electrochemical machining. EDM and electrochemical machining generally can only process conductive materials, not non-conductive non-metallic materials. Ultrasonic processing can not only process hard and brittle metal materials, but also is more suitable for processing non...

Principle Acoustic waves with a frequency exceeding 16000 Hz are called ultrasonic waves. Ultrasonic processing is a processing method that uses tools to vibrate at ultrasonic frequency and impact and polish the workpiece through abrasive particles. During processing, the tool acts on the workpiece with a certain pressure, the abrasive liquid is fed into the processing area, and the end fac...

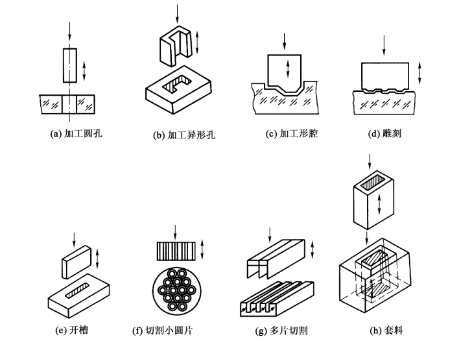

Different ultrasonic cutting processes The main role of the ultrasonic cutting process is to separate the connected components. The high frequency vibration per second can reduce the pressure on the item to be cut. This results in a neat and clean cutting surface. In practical applications, it is divided into two processes, separated welding and cutting. Separation welding Ultrasonic...

Ultrasonic cutting uses ultrasonic energy to cut objects. An electric pulse is sent through the cutter, creating microscopic vibrations in the blade. These vibrations are so small they cannot be seen or felt. The energy from the vibrations slices through an object with very little pressure required. Ultrasonic cutter vibrates its blade 20,000 – 40,000 times per second (20 – 40 kHz). ...

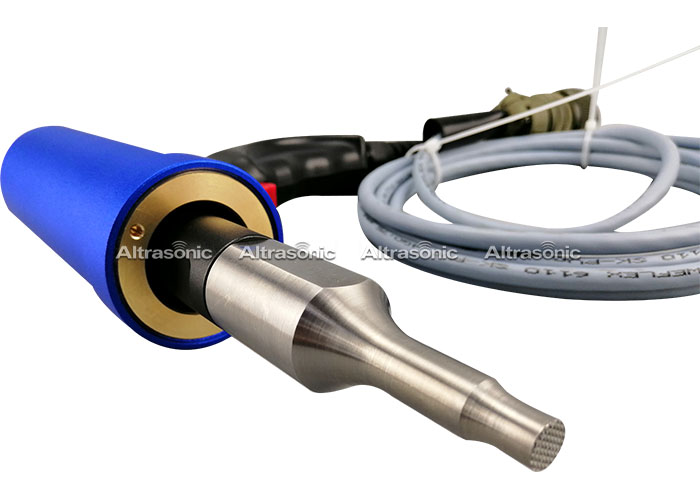

Parts of the ultrasonic welding: Ultrasonic welding machines are created to effectively convert electricity to mechanical vibrations. The machines come with a microprocessor to read the temperatures and regulate the heating accordingly. Some other components that make up the stack of the machine are: 1. Power supply: A high-frequency ultrasonic welding machine requires a...

Advantages of ultrasonic welding: Ultrasonic welding has many advantages when compared to traditional welding technologies. Many industries use ultrasonic welding due to these specific combinations of merits. Does not need external heat source: The primary advantage of ultrasonic welding is that it doesn’t need an external heat source. The heat is self-generated between the materials. Fast:...

Ultrasonic plastic welding is the joining or reforming of thermoplastics through the use of heat generated from high-frequency mechanical motion. It is accomplished by converting high-frequency electrical energy into high-frequency mechanical motion. That mechanical motion, along with applied force, creates frictional heat at the plastic components’ mating surfaces (joint area) so the plast...

There are many advantages to using ultrasonic assembly. It is a fast, clean, efficient, and repeatable process that produces strong, integral bonds while consuming very little energy. No solvents, adhesives, mechanical fasteners or external heat are required. Finished assemblies are strong and clean. Difficult materials can be assembled ultrasonically. Part assemblies are cycled quickly bec...

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat