Seldom will the ceramic component of a composite transducer have adequate tensile strength to withstand the high mechanical stress associated with the power demands for ultrasonic cleaning applications. The tensile strength of the ceramic elements can be supplemented by mechanically pre-stressing the elements along the direction of polarization. Pre-stress is introduced by incorporating a s...

As is true in many other applications for piezo¬electric materials, an assembly of multiple ceramic elements offers considerable performance and production advantages in ultrasonic cleaning transducers, relative to a single ceramic element. In order to provide the most efficient operation, simplify manufacturing, and reduce costs, more complex transducers intended for ultrasonic power appli...

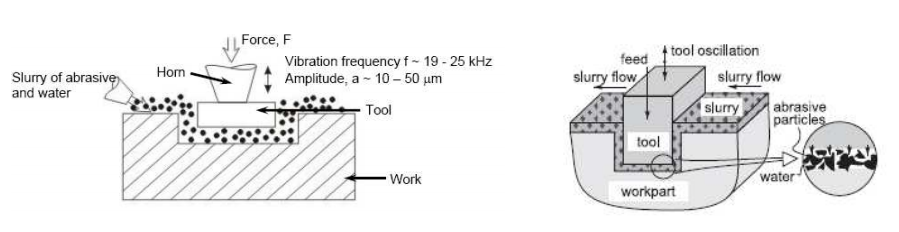

The vibration amplitude curve is shown in the following figure. There is no vibration at node, but the largest stress appears at these points. The machining efficiency is determined by the following factors, 1) Vibrational amplitude of the tool 2) Working pressure to the work piece 3) Condition of abrasive fed to the work piece Too large working pressure a well as too small pressure ...

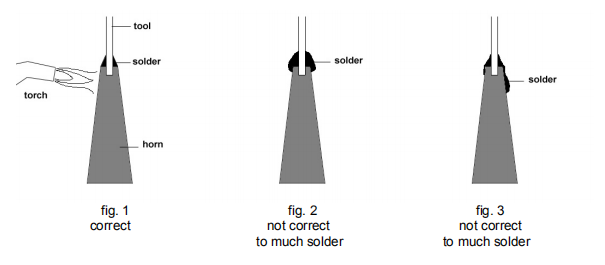

Solder a drilling tool onto the horn 1. Apply a little flux and silver solder onto the end of the drilling tool. 2. Put the drilling tool into position on the horn, and add flux to the joint. 3. Heat the horn with the gas torch, until the silver solder fuses and connects both pieces. 4. Do not heat exactly at the joint of tool and horn, but below on the horn. 5. When the drilling too...

Definition: Ultrasonic Machining is a non-traditional process, in which abrasives contained in a slurry are driven against the work by a tool oscillating at low amplitude (25-100 microns) and high frequency (15-30 kHz). Process: Ultrasonic machining is a mechanical type non-traditional machining process. It is employed to machine hard and brittle materials (both electrically conducti...

Process capability 1. Can Machine work piece harder than 40 HRC to 60 HRC like carbides, ceramics, tungsten glass that cannot be machined by conventional methods 2. Tolerance range 7 micron to 25 microns 3. Holes up to 76 micron have been drilled hole depth upto 51mm have been achieved easily. Hole depth of 152mm deep is achieved by special flushing techniques. 4. Aspect ratio 40:1 has been...

Tighten the set-screw in the cone. Clean the contact surface on both sides, transducer-cone and horn. Apply a drop of machine oil on both sides. Screw the horn onto the transducer-cone and tighten it with the provided tools. Set-up and adjusting of the feed-tray (The water thank is not supplied) Position the feed-tray with a proper inclination. Adjust the water-dripping device...

High power sine wave generator This unit converts low frequency (60 Hz) electrical power to high frequency (20kHz) electrical power. Transducer The high frequency electrical signal is transmitted to traducer which converts it into high frequency low amplitude vibration. Essentially transducer converts electrical energy to mechanical vibration. There are two types of transducer used 1...

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat