With the development of science and technology, ultrasonic spot welding machines have gradually come into everyone's eyes. With its own advantages, ultrasonic spot welding machines are taking up an increasing proportion of the welding market. Since the application of ultrasonic spot welding machine is so extensive, it is inevitable that there will be maintenance in the work, so what should we pay ...

Ultrasonic spot welder is a new type of equipment that uses the friction principle of ultrasonic high-frequency vibration to convert the energy of ultrasonic vibration into friction energy and transfer it to the surface of the metal to be welded. Under the conditions of the heat generated by friction and the pressure exerted on it, the metal structural molecules are fully activated to form a fusio...

The ultrasonic metal welding machine was discovered by accident in the 1930s. At that time, during the current spot welding and ultrasonic vibration test, it was found that the electrode could be welded without current, so the ultrasonic metal cold welding technology was developed. Although ultrasonic welding was discovered earlier, its mechanism is still not very clear. Ultrasonic metal welding a...

As the name suggests, the operating principle of the ultrasonic metal welding machine is to use the high-frequency vibration of the ultrasonic wave to transfer the welding metal surface, and apply a certain pressure to make the metal surface rub against each other to form the fusion between the molecular layers, so as to achieve the purpose of welding. Since the design of ultrasonic metal welding ...

Ø Ultrasonic welding The welding head (HORN) vibrating with ultrasonic ultra-high frequency, under moderate pressure, causes the joint surfaces of the two plastics to generate frictional heat and instantaneously melt and join. The welding strength is comparable to that of the main body. Suitable workpieces and reasonable interface design are adopted. It can achieve water tightness and air tightnes...

The effect of an ultrasonic welding machine is inversely proportional to the modulus of elasticity, coefficient of friction, and thermal conductivity, and inversely proportional to density, specific heat capacity, and melting point. The welding effect of the ultrasonic welder is mainly related to the melting point of the material and the surface friction coefficient. These parameters vary with mat...

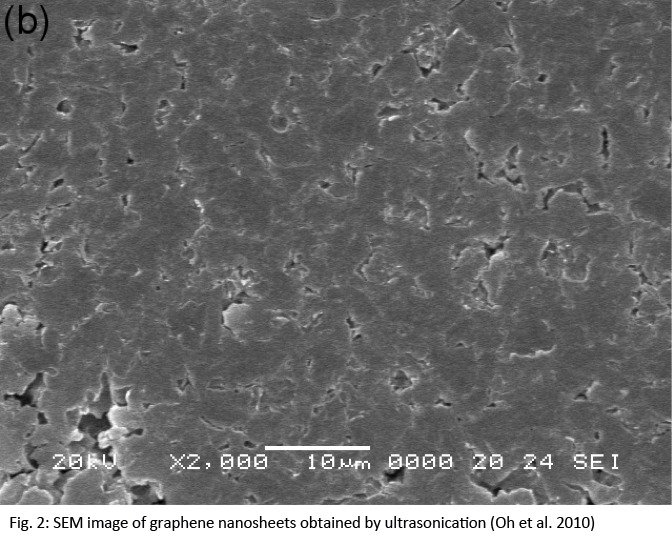

Ultrasonic preparation of graphene As the special properties of graphite are already known, several graphite preparation methods have been developed. In addition to chemically producing graphene from graphene oxide in a multi-step process, very strong oxidizing and reducing agents are also required. In addition, compared with graphene obtained from other methods, graphene prepared under these hars...

Ultrasonic energy acts on the medium, which will cause high-speed and subtle vibrations of the particles, resulting in changes in mechanical quantities such as speed, acceleration, sound pressure, and sound intensity, which will cause mechanical effects. Ultrasound is the propagation form of mechanical energy, which is related to the wave process and will produce a linear effect of vibration. When...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp