Today

ultrasonic welding is used in every industry that processes plastics. Most common

uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging

industries. Conforming to the spirit of "Service First", ALTRASONIC

provides lifetime maintenance to its products for as long as they are used by

customers.

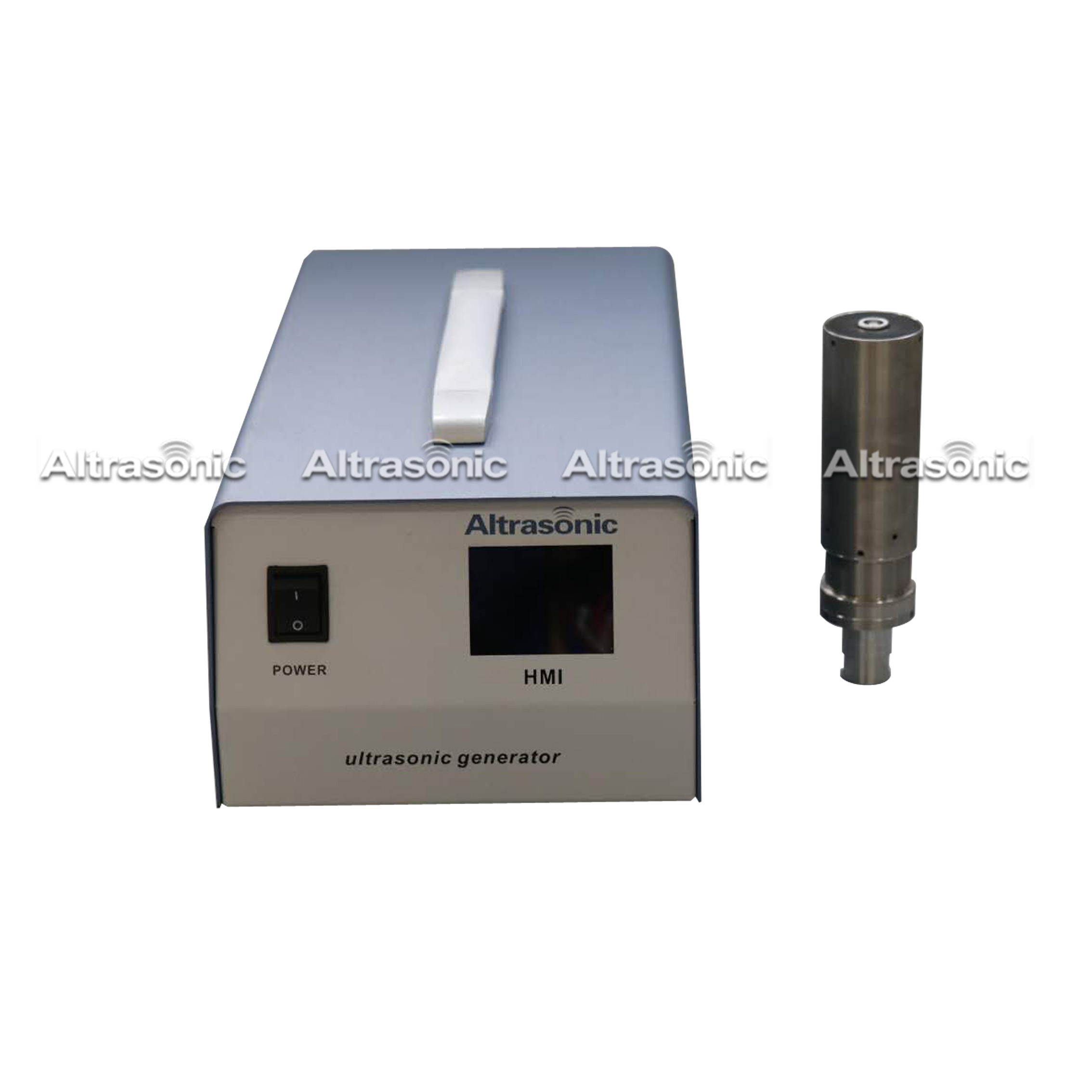

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Blue and SilverShipping port:

Ningbo or Shanghai

Ultrasonic welding 35kHz 1000Watt of PP, PVC, PE, PET

Description:

Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

Application:

|

Appliance |

In this high-volume market, hermeticity, strength and

also cosmetic appearance are important. Applications include: steam iron,

pump housing, vacuum cleaner wand, and dishwasher spray arm. |

| Automotive |

Hermetic seals in applications such as lenses, filters

and valves. Other applications include: glove box door, instrument cluster,

air diverter and mass airflow sensor. |

| Business |

"Clean" assemblies with reduced particulate

matter are produced on information storage discs. Other applications include

the assembly for ribbon cartridges, and audio and video cassettes. |

| Consumer |

Precision welding, staking and forming operations are

used in the manufacture of the Swatch®. |

| Electrical |

Multiple staking and inserting applications are often

automated for high-volume production requirements with consistent

reliability. Applications include: terminal blocks, connectors, switches

(e.g. toggle, dip, rotary quick and diaphragm), and bobbin assemblies. |

| Medical |

Non-contamination and the ability to be operated in a

clean room are as important as the strength of the weld. Reliable, repeatable

assemblies for critical life-support devices are produced with new

capabilities in process control. Applications include: arterial filter,

cardiometry reservoir, blood/gas filter, face mask and IV spike/filter. |

| Packaging |

From aseptic packages to toothpaste tubes, the ability

of ultrasonic assembly to seal through product contamination in the joint

area is a major advantage. In addition to good cosmetic appearance,

ultrasonic assembly provides tamper-evident seals for blister packs.

Applications include: condiment dispenser, blister package, juice pouch,

juice carton and plastic coated paper cups. |

| Toys |

In this highly competitive industry, the elimination of

adhesives, screws and solvents, or other consumables is a bonus added to

strong, safe, flash-free assemblies. |

Specification:

Item No. |

HSW35 |

Power |

1000W |

Frequency |

35kHz |

Generator |

Digital Generator |

Horn |

10mm |

Weight of horn |

1.0kgs |

Feature:

a. Suitable for welding pp, ps, pe, pc, abs, pbt, etc.;

b. No need any adhesives or flux, and less heat consumption;

c. Easy operation, high efficiency, excellent outward appearance, and high strength;

e. Automatic and manual operating mode, convenient for adjusting;

f. CE international quality certificate;

g. 1-year warranty.

Advantage:

1. Ultrasonic is the fastest, most repeatable and economical assembly method available to the industry today.

2. With ultrasonic, most thermoplastics can be assembled without heat, mechanical fasteners, or hazardous consumables such as adhesives or solvents.

3. Ultrasonic can join parts - small or large, simple or complex - with lower reject rates than any other method.

4. Using ultrasonic, labor - both as a skill factor and as a time factor - is significantly reduced. And since the equipment can readily be automated, any non-technical operator can be trained in minutes to produce high volume, high integrity assemblies.

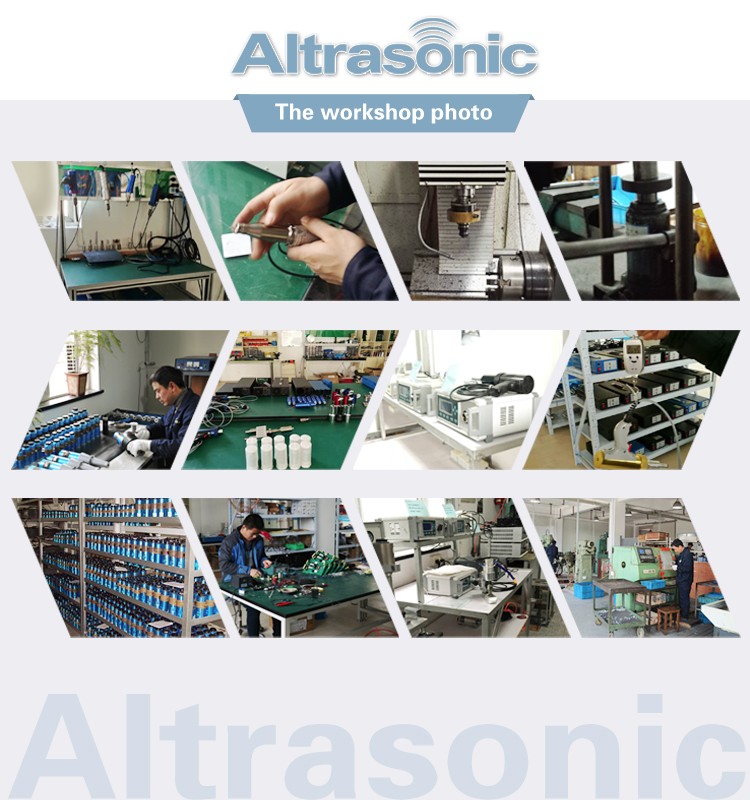

Workshop:

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Warranty:

One year Warranty with none human damage.In this period factory will responsible for repair fix it for free or factory will send the new parts to customer instead of the broken parts for free.After warranty time,factory will repair fix it or send the new parts on cost price

Quality control:

3 times old test to confirm the products is well quality.

20 technician work together , and learn together , to improve our products.

48 hours working time to test the stability of our product before sending out.

Previous :

35kHz Ultrasonic Spot Welding Welding Unit for Auto Interior SilencerNext :

Stacking Welding 28khz Mobile Less Weight Digital GeneratorIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp