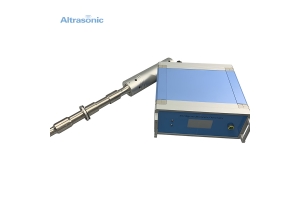

Ultrasonic 20K Sonochemistry Laboratory System

Ultrasonic 20K Sonochemistry Laboratory System

.

Product Details:

Place of Origin:

China

Brand Name:

Altrasonic

Certification:

CE

Model Number:

HS2020-L

Detailed Product Description:

Name:

Ultrasonic Sonochemistry Device

Frequency:

20Khz

Power:

2000W

Weight:

35Kg

Generator:

Digital Mode

Control:

Remote Control

Application:

Dispersing

Probe:

Different Size And Type Optional

Capacity:

More Than 100L

Lab level

Recommendation of ultrasonic system (exfoliated type)

Item No.

HS205-L

HS2020-L

Capacity

5L

20L

Output power

500W

2000W

Main advantages

High output intensity, high cavitation effect

Frequency

20 kHz±1kHz

Recommendation of ultrasonic system (Dispersing type)

Item No.

HS2010

HS2015

HS205-F

HS2010-F

HS2020-F

Capacity

20L

30L

10L

20L

30L

Output power

1000w

1500w

500w

1000w

2000w

Frequency

20 kHz±1kHz

20 kHz±1kHz

20 kHz±1kHz

20 kHz±1kHz

20 kHz±1kHz

Working type

Reactor / container

Reactor / container

Recycling

/ Flow chamber

Recycling

/ Flow chamber

Recycling

/ Flow chamber

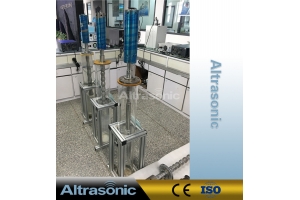

Recommendation of ultrasonic machine (Industrial level)

Ultrasonic Probe / Ultrasonic digital generator / Control system assembly / Reactor assembly / Rack and

pipe fittings

Item No.

HS-GS10

HS-GS25

HS-GS50

HS-GS100

HS-GS200

HS-GS300

Annual output

10tons

25tons

30tons

100tons

200tons

300tons

Output Power

2000w

2000w

2000w

2000w

2000w

2000w

Total Power

6000w

(2000w*3)

12000w

(2000w*6)

24000w

(2000w*12)

48000w

(2000w*24)

72000w

(2000w*36)

96000w

(2000w*48)

Frequency

20kHz±1kHz

20kHz±1kHz

20kHz±1kHz

20kHz±1kHz

20kHz±1kHz

20kHz±1kHz

Input Voltage

110v or 220v

110v or 220v

110v or 220v

110v or 220v

110v or 220v

110v or 220v

Total Volume

5㎡

10㎡

20㎡

40㎡

60㎡

80㎡

Introduction:

Ultrasound is a very effective processing method in the generation and application of nano-size materials. In general, ultrasonic cavitation in liquids may cause fast and complete degassing: initiate various chemical reactions by generating free chamical ions (radicals); accelerate chemical reactions by facilitating the mixing of reactant; produce highly concentrated emulsions or uniform dispersions of micron-size or nano-size materials. Ultrasound can be tested in lab and bench-up scale before the results are scaled up to the commercial level.

Advantages:

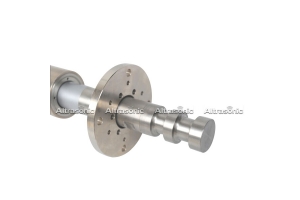

1. Core parts withTitanium materials.

2. Ultrasonic horn with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. Power adjustable from 1% to 99%

5. Frequency range from 19khz to 21khz

6. Lab and bench-up scale for testing

Innovation:

1. T caps use replaceable, solve the problem of the tool head cavitation, T caps normal working hours more than 800 hours.

2. Using the high-power ultrasonic transducer (1500w - 3000w), More stable performance, normal service life more than 10000 hours.

3. Use of the digitally controlled power, to ensure that all the time in the best condition.

4. Dumbbell-type tool head design, greatly improving the ultrasonic radiation power per unit area.

5. The integrated piping made of stainless steel #316.

6. Overall liquid flow-controllable

7. Use network-based CAN-bus technology, all working parameters can have room remote control.

Applications:

· Ultrasnic mixing

· Ultrasonic dispersing and deagglomeration

· Ultrasonic Emulsifying

· Ultrasonic Sonochemistry