Ultrasonic metal wire harness welding is used in the processing of metal wire harnesses, and is mostly used in electrical appliances and automotive industries.

Item No.:

HS-2050Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Silver and blackShipping port:

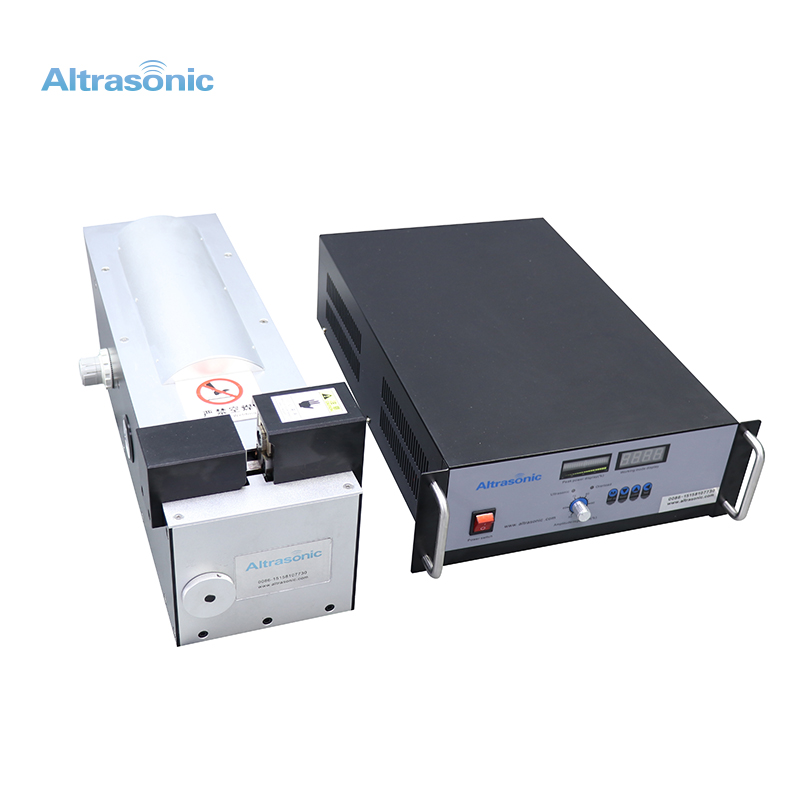

Shanghai or NingboUltrasonic metal wire harness welding machine Copper and aluminum wire welding Copper and aluminum braid welding

Description:

Ultrasonic wire harness welding machine is a derivative equipment of ultrasonic metal welding machine. Mainly used in the welding of copper wire and aluminum wire such as the welding of automobile wiring harness and motorcycle wiring harness. So it is often called automobile wire harness welding machine. One of the most important advantages of ultrasonic welding is the lower temperature. The generation of temperature is inevitable, it is only caused by friction, which is only 1/3 or 1/2 of the melting point of the metal. At the low temperature generated by the welding process, the metal wire retains its original performance due to annealing and the low temperature does not damage the insulation of the wire; in addition, the lower temperature also means that thin metal can be welded to thick metal Without causing damage to thin metal. These are very important in wire harness production.

Specifications:

Item No

HS-2050A

Frequency

20 kHz

Power

5000 watt

Welding area

0-35 mm²

Working air pressure

0.05-0.9 MPa

Weight

55 KG

Generator size

500*400*160 mm

Machine size

600*200*260 mm

Characteristic:

1. The welding area of the ultrasonic wire harness welding machine can be adjusted.

2. The ultrasonic wire beam welding machine can reduce the temperature effect of the material to a relatively low level (the temperature of the welding zone does not exceed 50% of the melting temperature of the welded metal), so that the metal structure does not change, so it is very suitable for welding applications in the electronic field.

3. Compared with the resistance welding method, the ultrasonic harness welding machine has a long mold life, less time for mold refurbishment and replacement, and it is easy to realize automation.

4. Ultrasonic wire-beam welding machine can perform ultrasonic welding between the same kind of metal and different kinds of metals, which consumes much less energy than electric welding.

Workshop:

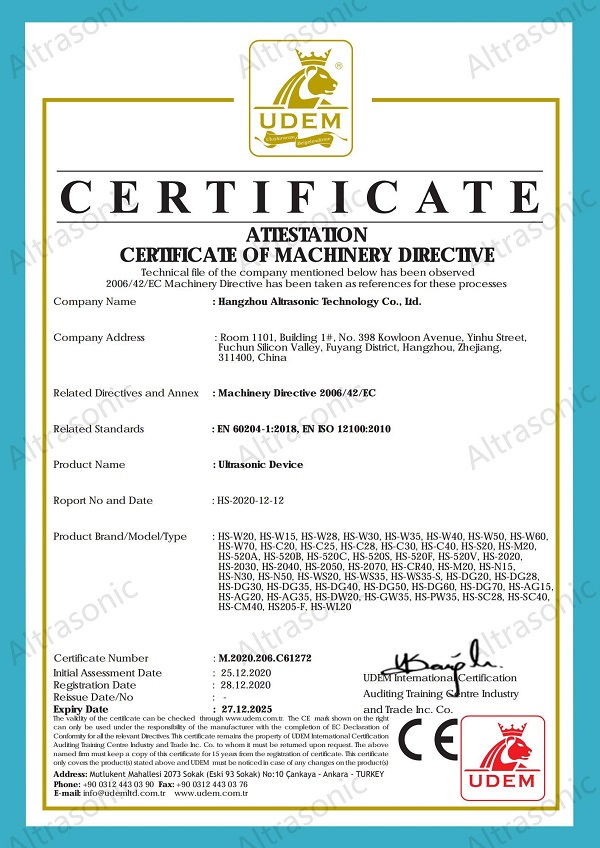

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Automobile wire harness welding machine Multi-strand copper wire square welding machineNext :

Ultrasonic Aluminum-plastic Pipe Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp