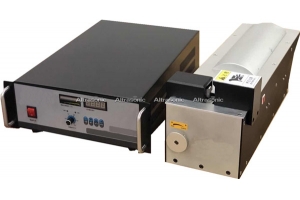

20khz Ultrasonic Crushing Machine, Used For Crushing Animal And Plant Tissues, Cells, Bacteria And Spores

Ultrasonic pulverizer is a kind of multi-functional and multi-purpose instrument that uses strong ultrasound to produce cavitation effect in liquid and ultrasonically treat substances. It can be used for breaking animal and plant tissues, cells, bacteria, and spores. To emulsify, separate, disperse, homogenize, extract, degas, clean and accelerate chemical reactions. This machine is widely used in teaching, scientific research and production in the fields of biochemistry, microbiology, medicinal chemistry, surface chemistry, physics, zoology, agronomy, medicine, pharmacy, etc.