Ultrasonic assisted machining is a recently-developed technique, in which high-frequency (> 20 kHz) vibration is superimposed onto the movement of a standard drill bit in the axial direction, providing advantages including reduced drilling forces (reduction often in excess of 80%) and improved quality of drilled holes when compared to conventional drilling.

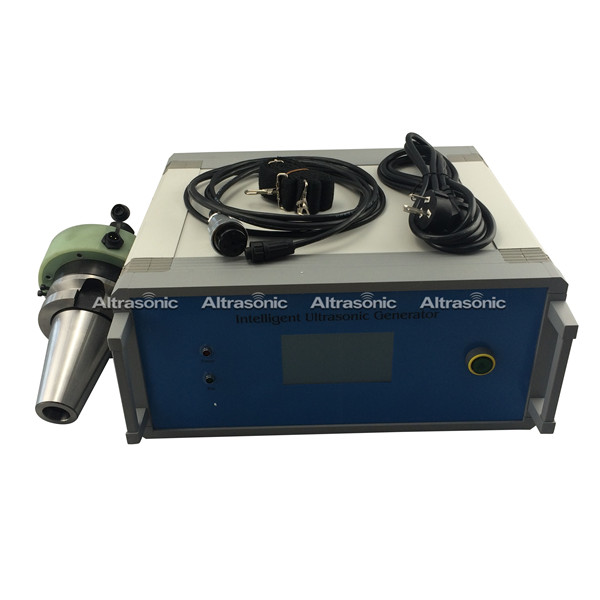

Item No.:

HSM20Product origin:

China

Ultrasonic Assisted Processes Vibration For Machining Of High Precision Material

Technical Parameters:

Product shape: milling machine handle

Resonance point amplitude: 10um or more;

Speed: 30000 r / min or less

Matching tool: carbide end mill head Φ2-Φ13; disk cutter Φ50;drilling hear Φ1~Φ13

Power: 500W

| Frequency | 20 Khz/40Khz |

| Output Power | 500 W |

| Voltage | 220 V |

| Switch | Handle or foot switch |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weight | 30 KG |

| Application | Ultrasonic drilling |

| Generator | Digital Generator |

| Length of cable | 5M |

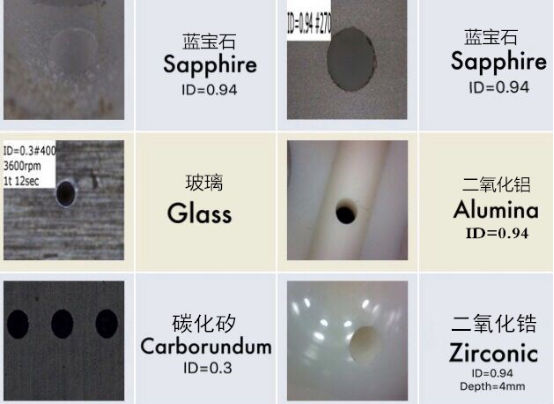

Ultrasonic Machining:

Ultrasonic assisted machining is a recently-developed technique, in which high-frequency (> 20 kHz) vibration is superimposed onto the movement of a standard drill bit in the axial direction, providing advantages including reduced drilling forces (reduction often in excess of 80%) and improved quality of drilled holes when compared to conventional drilling. Ultrasonic assisted drilling also achieves a reduction in entry and exit delamination size, but not in the expected proportion considering the observed reduction of drilling forces. A different mechanical process to that in conventional drilling may be driving the delamination in Ultrasonic assisted drilling, for example dynamic or thermal effects in addition to thrust and torque loads.

The aim of this project is to achieve a mechanical understanding of the process that drives delamination during Ultrasonic assisted drilling and to implement it in an analytical model and numerical tools with predictive ability. These can then be used to enhance Ultrasonic assisted drilling to minimise delamination and to predict the performance of hybrid joints with Ultrasonic assisted drilling-induced damage.

Principle:

Ultrasonic machining offers a unique blend of capabilities, quality and material compatibility for the machining of engineered ceramics and advanced technical materials. The process is versatile, offering flexibility to meet a wide range of design requirements, and yields high-quality parts with little or no subsurface damage and no heat-affected zone. These benefits make it a valuable resource for the scientists, engineers and designers who are developing tomorrow’s advanced technologies.

An added benefit is that parts machined ultrasonically often perform better in downstream machining processes than do parts machined using more conventional machining methods. The improved performance can result in economic advantages from higher yields, lower scrap and operating costs, and improved efficiencies

Applications:

Product details:

Workshop:

CE Certification:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

FAQS:

Q:Can your ultrasonic machine assemble to my CNC machine?

A:Yes, you need to inform us the type of tool holder like BT/CTA/ISO/HSKA , or you can provide drawings that we will customized the same on our ultrasonic part to match your CNC machine.

Q:What is the RMP(Round Per Minute) pf your equipment?

A:Normally the max speed of designed equipment is below 3000RMP, if you need faster for better performance, we will do the some adjustment to match the max speed 30000 RPM.

Q:What is the diameter of your drilling tool?

A:The diameter range of our drilling tool is 1mm to 13mm(according to custom’s application)

Previous :

Mechanical Nontraditional Ultrasonic Machining with Horns Made of Steel or TitaniumNext :

Rotary Ultrasonic Hybrid Machining Process For Hard Brittle Ceramics CompositesIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp