Non-Woven Welding By Ultrasonic Welding Gun

Product origin:

ChinaProduct weight:

13KgNon-Woven Welding By Ultrasonic Welding Gun

|

Minimum Order Quantity: |

1 Set |

|

Price: |

|

|

Packaging Details: |

Wood case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

500 Sets/Month |

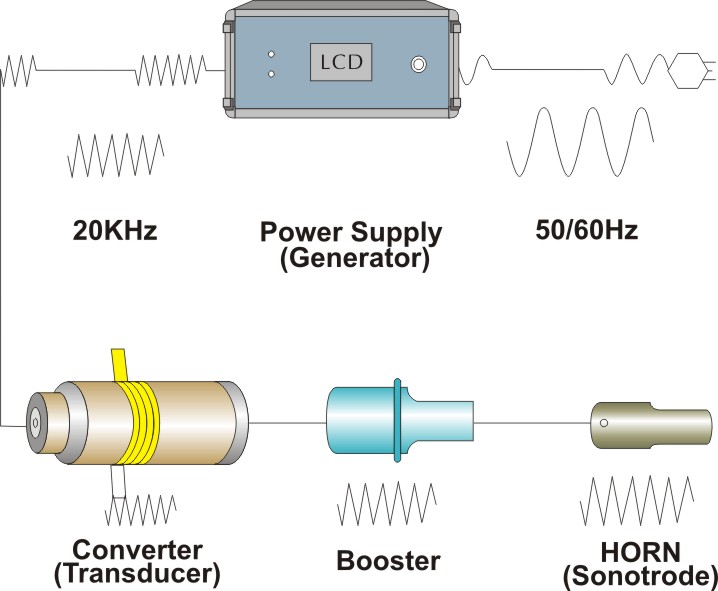

ULTRASONIC HANDGUN WELDING SYSTEM

The ultrasonic handgun is ideal for spot welding plastic sheet and attaching non-woven materials using a variety of standard and application specific horns. This unit can be set to weld continuously or by time for repeatable and consistent welds. Two weeks lead time.

STANDARD FEATURES

Weld by time or continuous duty.

Compact and portable power supply with overload protection.

Lightweight handgun with pushbutton actuation.

Accepts a wide range of standard and custom 35kHz horns.

Description

Another benefit is the time of glycerol separation.This is also faster and one of the reasons for it is that less methanol is been used,so glycerol separation is faster.

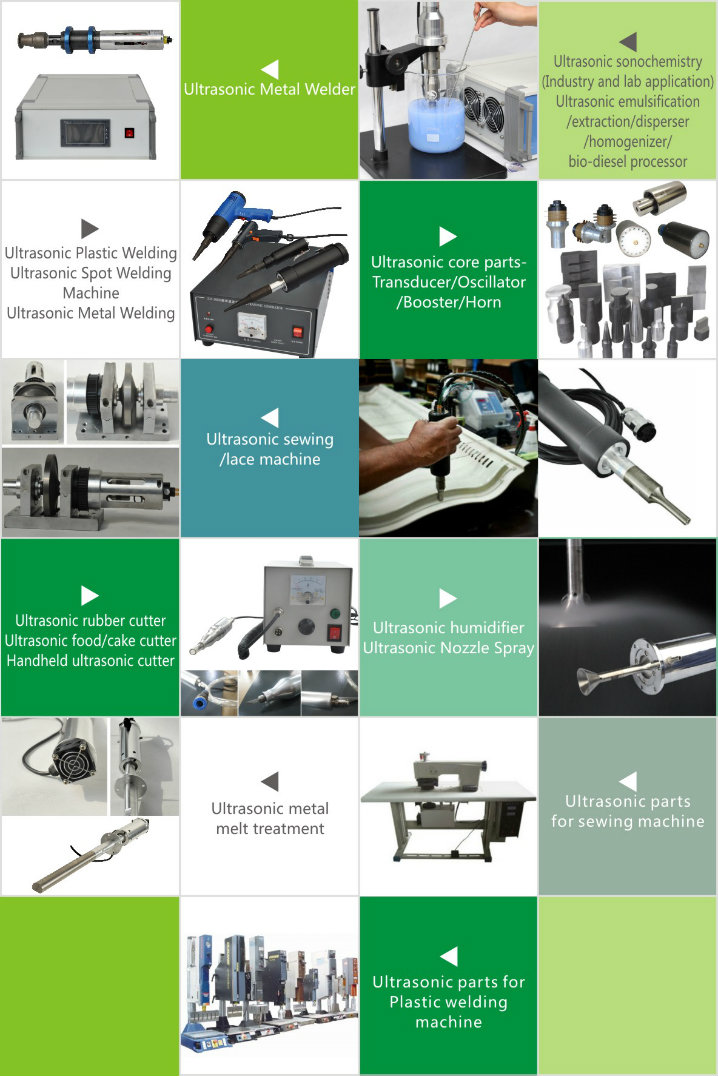

Hand held ultrasonic welding machines, also known as portable ultrasonic welding machines,hand held ultrasonic welding machines, handheld welding machine, portable welding machine, ultrasonic spot welding, riveting machines, ultrasonic point welder, can be used for the butt welding of thermoplastics, welding head can also be replaced according to customer demand for riveting, spot welding, embedding, removal process, compared to other traditional crafts (such as adhesive, scald together or screw fastening, etc.), with high production efficiency and welding quality good, environmentally friendly and energy-saving advantages.

Manufacturers of underwear, surgical masks, medical shoes and bedcovers, among other segments, have already extensively adopted the ultrasound technology, due to its highly resistant hermetical sealing. This technology presents yet more advantages when compared to the usual sewing methods, such as the joining of different types of materials, strong binding quality, no fiber melting beyond the welding area and a stitchless finishing. This system consumes very little energy on stand-by, does not need any adhesives and can dramatically increase the production capacity.

Packing

The welded parts do not present any rough edges and the process does not exhale any odors or smoke. It allows for the joining of transparent parts without any crystallization mark.

This way, the process can be employed in the manufacturing of packages for food and hygiene products, as well as products consisting of internal subsets.

It also allows for the processing of flammable or explosive products without any risk of ignition or explosion.

The process is also normally executed in one second, without the need for an extended cooling and/or drying time.

Specifications:

|

|

Gun Type |

Cylinder Type |

||||||

|

Model |

|

|

|

|

|

|

||

|

Frequency |

35k |

28k |

28k |

20k |

28k |

28k |

28k |

|

|

Power |

700 |

300&500 |

400&700 |

900 |

300&500 |

400&700 |

500&800 |

|

|

Horn |

≤10mm |

≤10mm |

≤12mm |

≤13mm |

≤8mm |

≤12mm |

≤12mm |

|

|

Housing Diameter |

51mm |

64mm |

40mm |

45mm |

60mm |

|||

|

Handle Size |

100mm×45mm×32mm |

—— |

—— |

—— |

||||

|

Weight Without Wire and Horn |

0.6kg |

1.3kg |

1.3kg |

1.5kg |

0.6kg |

0.6kg |

1.3kg |

|

|

Digital generator |

● |

● |

● |

● |

— |

● |

● |

|

|

Analog generator |

● |

● |

● |

● |

● |

● |

● |

|

Pistol type: in accordance with the shape design of human body engineering, ultrasonic start switch is located on the trigger, easy to grasp and use the welding operation, especially suitable for horizontal or vertical.

Straight type: for the appearance of design straight, ultrasonic start switch is located outside the cylinder, easy welding and hand carried, can also be installed between the on machine, welding operation for each direction.

Competitive Advantage:

★Efficiency: The welding process is very fast, welding time is only 0-999 seconds.

★Strength: Can bear more pressure and tension (the weld joint has same strength as the base material).

★Quality: Finished product is hermetic sealing (airtight and watertight).

★Cost: Non bolt or glue, reduce labor and costs (no adhesives, screws, connective bolts).

★Appearance: The joints are repeatable, clean and precise.

Previous :

Automotive Lamp Weding By Ultrasonic EquipmentsNext :

35KHZ ULTRASONIC HANDGUN WELDING SYSTEMIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp