The ultrasonic welding is a very quick process, thus being the most effective solution for mass production. This type of welding is employed in the automotive industry and in the manufacturing of electronic products such as computers, pendrives, keyboards etc. The ultrasonic welding can be applied on the following plastic types: PET, polypropylene, polycarbonate, polyoxymethylene, nylon, acr...

Principles of ultrasonic technology for ultrasonic horns and transducer test and design Ultrasonic transducers and horns and acoustic sets are devices which convert electrical energy into vibration. To understand the operation principles, it can be done an analogy between an ultrasonic welding set and an automobile. The transducer performs the energy conversion (as the motor), the tra...

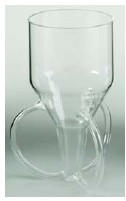

Ultrasonic plastic welding machines involves the use of high frequency sound energy to soften or melt the thermoplastic at the joint. Parts to be joined are held together under pressure and are then subjected to ultrasonic vibrations usually at a frequency of 20, 30 or 40 kHz. The ability to weld a component successfully is governed by the design of the equipment, the mechanical properties o...

Ultrasonic plastic welding is a kind of thermoplastic jointing technology, which makes use of friction between molecules generated by ultrasonic horn. During ultrasonic welding, two plastic part halves are pressed together under pressure, ultrasonic system transform electric energy in 50/60Hz into mechanical energy in 15KHz, 20KHz, 28KHz, 30Khz, 35Khz, 40Khz by convertor, and strengthens it by boo...

Ultrasonic equipment is in use process, inevitably generator fault. A number of reputable manufacturers, warranty period in a year, will do a good job in a timely customer service work. Sometimes in order to emergency or already over warranty period, ultrasonic fault has occurred, please contact us directly repair: we can offer you repair services are as follows: Repair of ultrasonic cleanin...

Supercritical fluid extraction assisted by power ultrasound s is a new process based on the application of high-intensity ultrasound to accelerate the extraction effect of supercritical CO2. The new technology has shown to be efficient in a semi-industrial installation Supercritical fluid extraction (SFE) is a separation process based on the contact of a substance containing the extractable ...

Introduction Three general types of reactors are used for biodiesel production: batch reactors, semi-continuous-flow reactors, and continuous-flow reactors. The batch process is inexpensive, requiring much less initial capital and infrastructure investment. It is flexible and allows the user to accommodate variations in feedstock type, composition, and quantity. The major drawbacks of the ba...

Ultrasonic Welding Ultrasonic welding is the process by which two pieces of plastic are joined together through the use of high-frequency acoustic vibrations. For the process one half of the component is placed on a fixed anvil and the second half is placed on top. An extension, connected to the transducer on the welding machine, called a “horn” is then lowered down on top of the two compone...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp