Altrasonic's efficient cutting tools enable food industry companies to enhance performance and improve slicing operations. The principle is simple: the end of the oscillating knife (sonotrode) is set as needed at a defined amplitude (30 to 100 µ) and frequency (20 or 30 kHz). It creates an acceleration of more than 105 G, cutting the food into pieces, with the help of a press that moves up and dow...

Compared with the traditional pneumatic two-fluid spraying, ultrasonic spraying equipment can achieve better uniformity, thinner coating thickness and higher precision. At the same time, because the ultrasonic nozzle can be atomized without the aid of air pressure, the use of ultrasonic spraying can significantly reduce the splashing of paint during the spraying process and realize the purpose of ...

Every textile welding application is different and requires an in-depth understanding of the challenge-and the technology required to solve it. Our ultrasonic textile solution has low energy consumption and does not require the use of commercial materials such as glue, clips or yarn. From disposable medical products to disposable diapers, consider solving your textile application challenges. Medic...

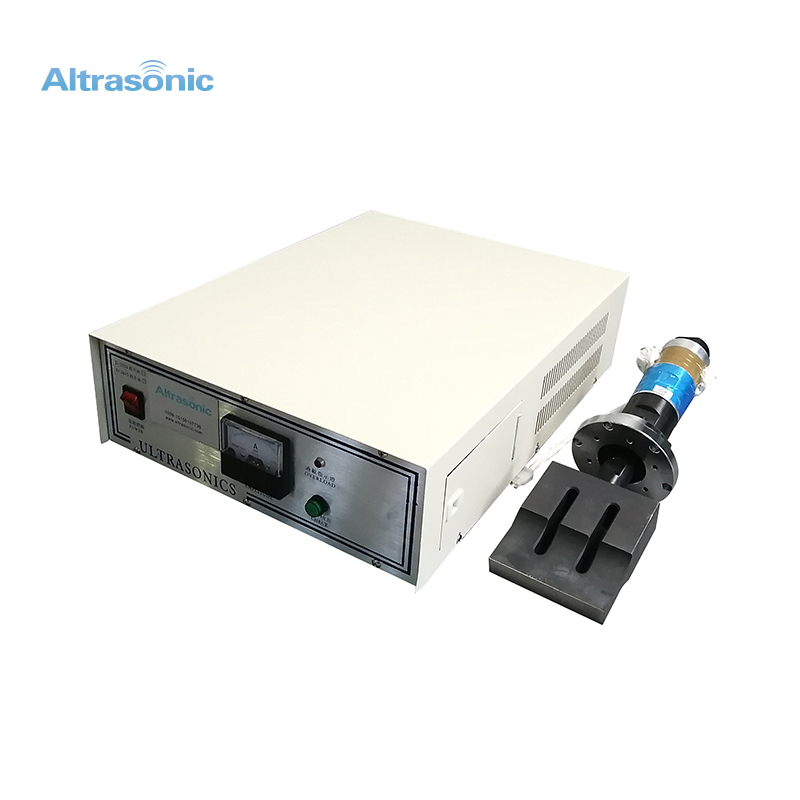

Ultrasonic food cutting machine is a kind of equipment that uses ultrasonic energy to cut. Its characteristic is that there is no cutting edge in the traditional sense. We provide complete professional equipment and components for ultrasonic food cutting. Compared with traditional cutting machines, ultrasonic food cutting machines are more hygienic, with shorter downtime, higher cost performance, ...

The design basis of the working frequency of the transducer involves the attenuation of ultrasonic energy by the sound transmission medium, the reflection characteristics of the detection target (such as defects) on the ultrasonic wave, the background noise of the sound transmission medium and the radiation impedance, etc. There are many influencing factors that determine the working frequency of ...

Compared with the traditional pneumatic two-fluid spraying, ultrasonic spraying equipment can achieve better uniformity, thinner coating thickness and higher precision. At the same time, because the ultrasonic nozzle can be atomized without the aid of air pressure, the use of ultrasonic spraying can significantly reduce the splashing of paint during the spraying process and realize the purpose of ...

As an energy conversion device, the ultrasonic transducer can efficiently and stably convert electrical power into mechanical power (ultrasound) during the conversion process, but there will still be losses in the actual process. According to the law of conservation of energy, it must be Reactions occur in other places, such as heating of the ultrasonic transducer. The first reason for the heating...

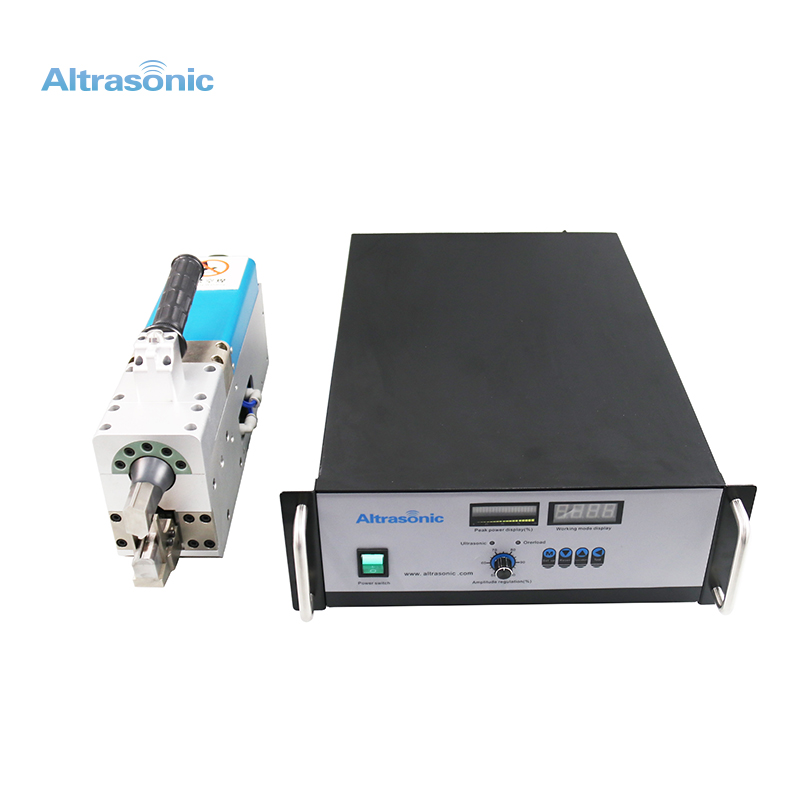

Ultrasonic welding uses an ultrasonic generator to convert 50/60 Hz current into 15, 20, 30 or 40KHz high frequency electrical energy. The converted high-frequency electric energy is again converted into mechanical motion of the same frequency through the transducer, and then the mechanical motion is transmitted to the welding head through a set of horn devices that can change the amplitude. The w...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp