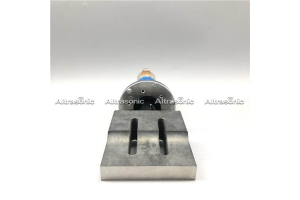

70Khz Ultrasonic Plastic Welding System For PE Material Staking

Today ultrasonic welding is used in every industry that processes plastics. Most common uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging industries.Conforming to the spirit of "Service First", ALTRASONIC provides lifetime maintenance to its products for as long as they are used by customers.