The ultrasonic welding machine can weld non-woven fabrics very well, and it is environmentally friendly, sterile, efficient and strong.

Item No.:

HS-W20Payment:

T/T, PayPal, West UnionProduct origin:

ChinaColor:

SilverShipping port:

Shanghai or NingboLead Time:

15One to One Inner Ear Plane Mask Automatic Making Machine Plus Ear Loop Spot Welder

Description:

One to one Plane Mask machine, including feeding, plastic strip type aluminum strip insertion / unfolding, scene selection, ultrasonic fusion, slicing, etc., are fully automated. We are using 1 unit of Blank Mask Making Machine to match with 1 unit of Ear-Loop Welding Machine during mass-production.The output is extremely high, which can produce 1-80 pieces per minute. The main power is frequency-converted, which can be fast or slow. Different masks can be produced using different materials. The product has two layers and three layers. The product has stable quality, convenient operation, low noise and small footprint.

Specification:

Voltage: single phase 220V / 50kz

Power: 5,000Watt

Working pressure: 5,000-8,000gf

Size: 4278 * 1915 * 1859

Output: 80 pcs / minute

Delivery time: 15 working days

Staffing: 1 person to manage 3-5 machines

Work Process:

1. 3/4 mask roll material feeding

2. Folding and pressing-nasal bridge tendon feeding

3. Ultrasonic welding interface mask molding

4. Mask cutting

5. Ear band cutting and ultrasonic welding

6. Finished product output-counting-finished product output

Feature:

1. The frame is made of aluminum alloy and stainless steel, which is light and beautiful and does not rust;

2. Automatic counting can effectively control production efficiency and production progress;

3. Frequency conversion control, which can adjust the operating speed of the equipment according to actual needs;

4. Pull the barrel to feed, more accurate positioning, which can minimize the width of raw materials and save costs;

5. Uniform length and size control of the finished product with a deviation of ± 1mm can effectively control the length of the finished product;

6. The equipment has a high degree of automation and low requirements for operating staff, and only needs to discharge and arrange the finished product;

Workshop:

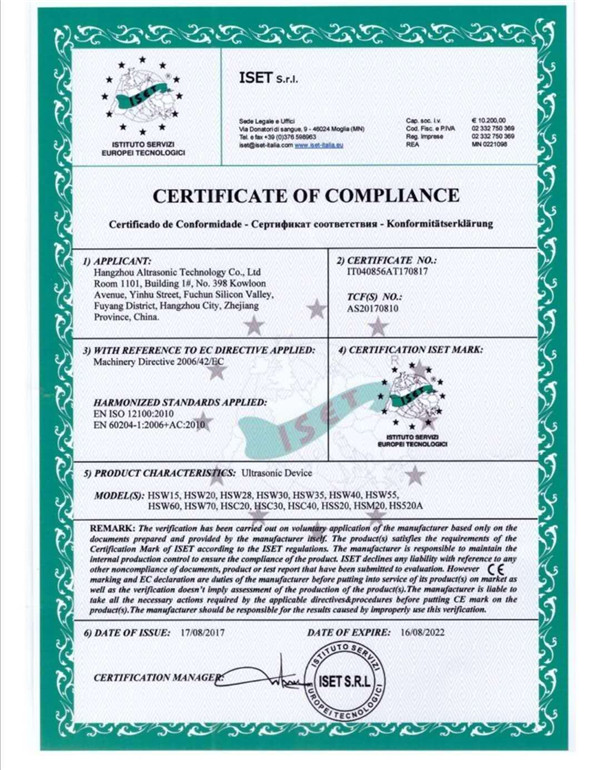

CE:

Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Quality:

3 times old test to confirm the products is well quality.

20 technician work together , and learn together , to improve our products.

48 hours working time to test the stability of our product before sending out.

Previous :

Mask Ear Loop Manual Ultrasonic Spot Welding Machine 35kHz 800WattNext :

15kHz 2600Watt Ultrasonic Converter and Booster with Welding Horn 200*25mmIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp