Ultrasonic Degating: Fast, Clean Plastic Part Separation In the world of plastic injection molding, ultrasonic degating is the high-speed, "clean-cut" alternative to manual trimming. It uses high-frequency mechanical vibrations to separate molded parts from their runners or gates. If you’ve ever snapped a plastic model piece off a frame and left a jagged white stress mark behind, you’ve seen why d...

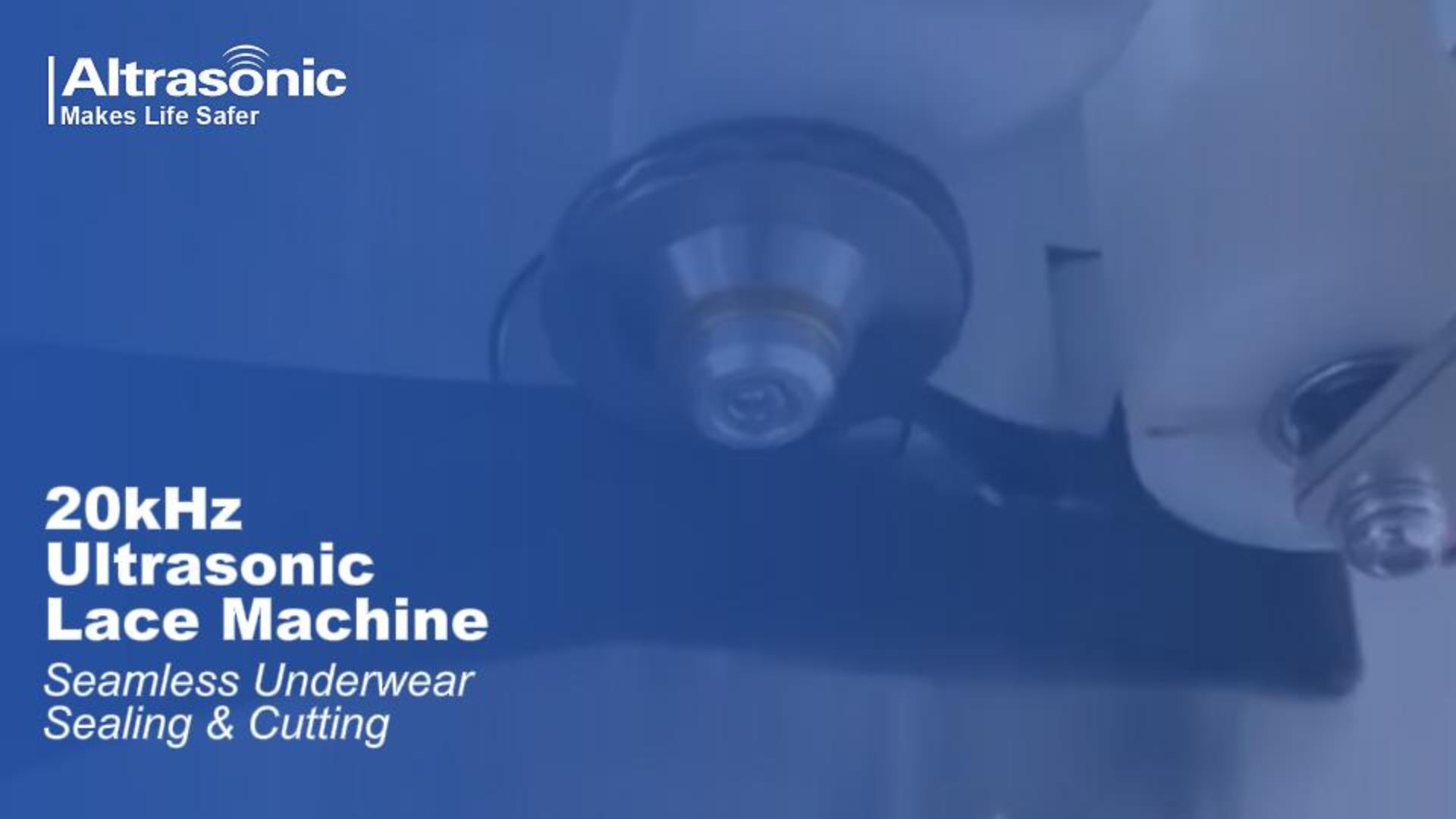

In the production of seamless underwear, ultrasonic technology uses high-frequency vibration energy to precisely weld and cut materials, replacing traditional sewing processes. Its core applications include: Edge cutting and fusing: Ultrasonic pattern wheels are used to seamlessly cut and fuse the edges of underwear, resulting in smooth, soft edges that resist ripping and tearing, while also prese...

I. Advantages of Ultrasonic Welding for Non-woven Fabrics Efficient and Pollution-free Welding No traditional needles, threads, or adhesives are required. Instead, high-frequency vibrations cause the thermoplastic components of non-woven fabrics (such as PP and PET) to melt and bond locally, avoiding adhesive residue or chemical contamination and meeting medical and hygiene product standards. Pres...

Looking for an ultrasonic cutting machine that can smoothly cut through thermoplastic materials? Don't miss our 40kHz ultrasonic cutting machine. Watch the video below to see it in action: Specifications: Frequency: 40kHz Power: 100W Voltage: 220V/110V Shell material: Aluminum Generator: Analog generator Generator size: 265*156*170mm (L*W*H) Cutter size: Φ32*170mm Generator weight: 3.6kg Cutter we...

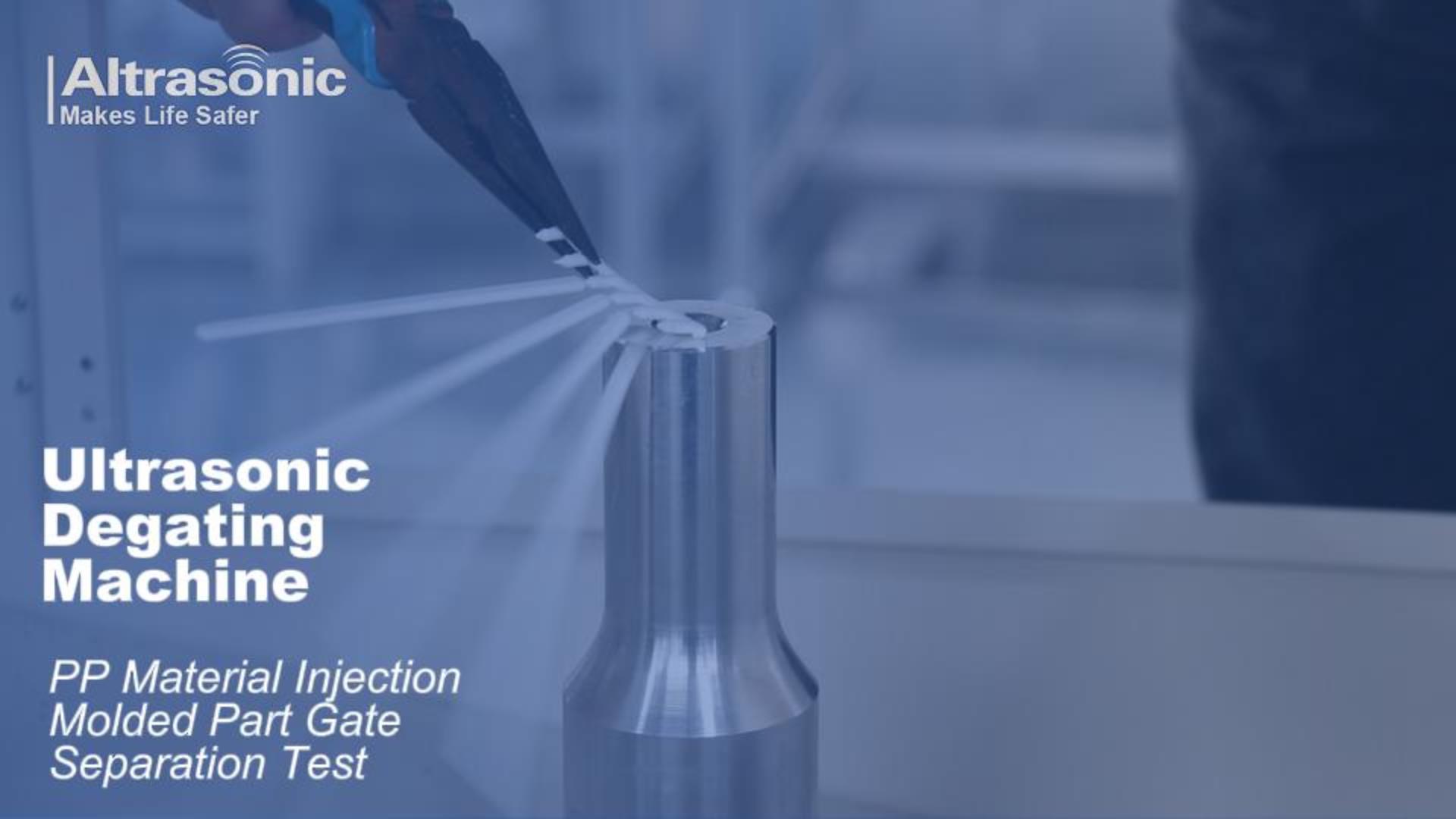

Looking for a clean and efficient solution to remove injection molding gates? Don’t miss out on our high-quality ultrasonic degating machine. Watch the video below to see the operation and performance of our ultrasonic degating machine: Ultrasonic Gate Cutting Machine is a specialized machine used to remove gates (runner ports) from injection-molded parts. By utilizing ultrasonic energy, it genera...

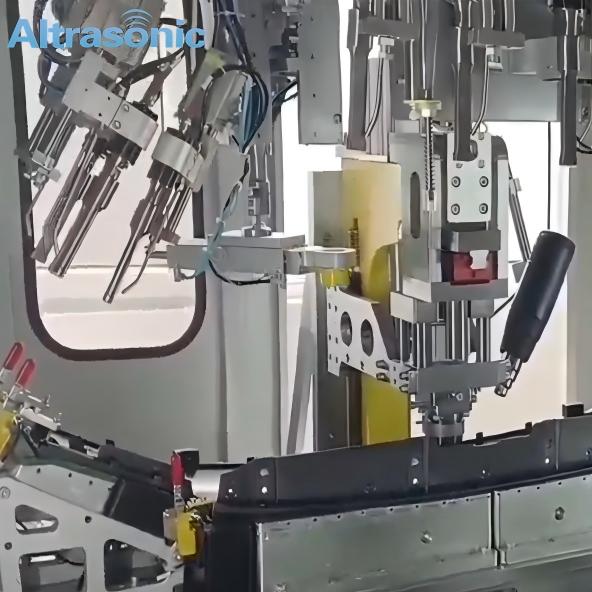

Experience High-Efficiency Welding with Our Automated Ultrasonic Multi-Head Welding Machine Come and watch how the Automated Ultrasonic Multi-Head Welding Machine precisely welds automotive parts in the video below: Key Advantages: 1. Each welding unit is equipped with an opposite buffer limiter, and the size of the welding position can be adjusted 360 degrees. Each welding head unit is selected a...

Altrasonic’s Ultrasonic Sleeve Welding Machine is a high-performance system designed specifically for the sealing and welding of sleeves made from synthetic and blended fabrics. It offers multiple intelligent functions such as frequency tracking, amplitude adjustment, automatic overload protection, primary overcurrent pulse handling, overheating protection, secondary overcurrent adjustment and pro...

HS-520S Ultrasonic Power (Sound Intensity) Meter Precisely measure the most critical parameter in ultrasonic applications: Sound Intensity (Power Density) within liquid media. Ideal For: Ultrasonic cleaning tanks Sonochemical processing Descaling operations Dispersion & cell disruption Cavitation energy assessment Why Measure Sound Intensity? The effectiveness and efficiency of your ultrasonic...

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp