Rub your hands quickly and they will warm up. The heat is caused by friction. Now imagine rubbing your hands hundreds of times per second! The frictional heat generated can significantly increase the temperature in a short period of time.

Similarly, high-frequency sound (ultrasound) can cause rapid vibrations in the materials to be connected together. Vibration causes materials to rub against each other, and friction increases the temperature of the contact surface. This rapid frictional heat is a condition for the materials to bond together.

Ultrasonic welding in electronic contract manufacturing

Blog theme

Custom cables

Electronic Manufacturing Service

Manufacturing Technology

Injection molding

Precision Machining

Secondary service

Testing and quality

Value-added services

The Process

Ultrasonic welding technology introduced in the 1940s uses high-frequency sound waves and pressure to bond metals together. This technology is very suitable for welding non-ferrous materials such as aluminum, brass, copper and nickel.

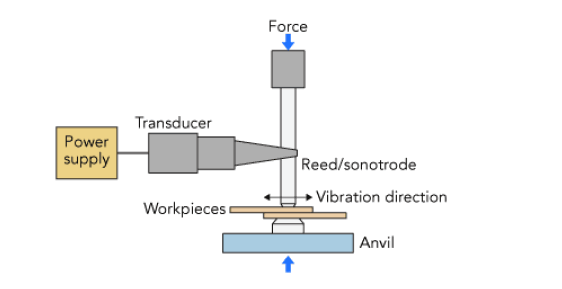

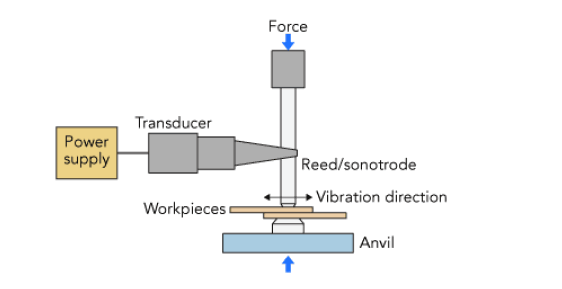

In the simplest form, ultrasonic welding uses a vibrating tool called a horn, which transmits ultrasonic energy to the area where the parts to be connected meet. Ultrasonic vibration decomposes the oxide and film on the surface of the part, so that the metal/workpiece can be in direct contact. When the ultrasonic vibration stops, a solid bond is formed.

Let us take a closer look at the basic elements of an ultrasonic welding system.

1.) A pneumatic or electric press used to assemble two parts under pressure.

2.) A fixture that is used to place parts and allow high-frequency vibrations to be directed to the interface.

3.) Ultrasonic stack composed of three components. All three components are tuned to resonate at the same frequency (usually 15-40kHz)

a.) Converter: Use the piezoelectric effect to convert electrical signals into mechanical vibrations.

b.) Booster: Mechanically modify the amplitude of vibration.

c.) Horn or ultrasonic generator: adopt the shape of the part, modify the amplitude mechanically, and apply mechanical vibration to the part.

4.) The power supply provides high-power electrical signals with a frequency that matches the resonant frequency of the stack.

5.) A controller that controls the movement of the press and the transmission of ultrasonic energy.

The Advantage

Ultrasonic welding has many advantages.

increase productivity. The machine heats up and cools quickly. The assembly process can be highly automated, providing strict control over dimensional tolerances. The welding time is usually less than 1 second. In addition, the assembler does not have to worry about allocating time for preheating or cooling. The total cycle time is very short.

Clean surface: Ultrasonic welding will not damage the surface finish, because high-frequency vibration can prevent marks. There is also no need for a ventilation system to remove heat or exhaust.

save costs. Compared with traditional welding, the power consumption is extremely low.

Application

Due to its overall efficiency and productivity improvement, ultrasonic welding is now widely used in various industries, including wire harnesses, sheet metal, plastics, auto parts and medical equipment.

Electronics industry-Ultrasonic welding is often used to connect wired connections and create connections in small precision circuits.

Sheet metal and precision machining-Aluminum is a metal that is difficult to weld using traditional techniques because of its high thermal conductivity. However, aluminum is easy to weld using ultrasonic welding because it is a softer metal, so solid-state welding is easy to achieve.

Medical equipment-In the medical industry, ultrasonic welding is often used because it does not introduce contaminants or degradation in the weld, and the machine can be dedicated to clean rooms.