Advantages of Ultrasonic Welding over Laser Welding

Ultrasonic welding is the use of high-density energy generated by ultrasonic high-frequency mechanical vibration to produce plastic deformation on the surface of the workpiece and destroy the surface layer under pressure, so that the welded metal is physically connected at room temperature. Although ultrasonic welding will destroy about 3% of the film layer, because it is a continuous non-melting welding, the heat conduction efficiency is relatively good. At the same time, ultrasonic welding has certain advantages in terms of material cost. Ultrasonic welding is suitable for thin products. The copper plate of mainstream flat products in the world is generally between 0.12mm and 0.2mm. In order to consider the material cost, some enterprises now choose aluminum plates and ultrasonic welding choose 0.2mm. -0.3mm is enough. Laser welding is suitable for thick materials. For example, the thickness of aluminum plate is generally selected to be 0.4mm, resulting in higher material cost.

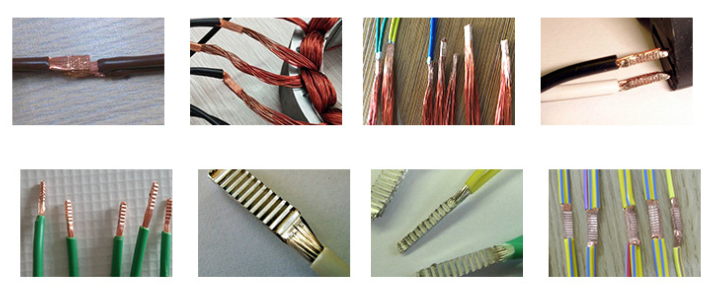

Ultrasonic metal spot welding machine is used for the same type of metal welding, and can perform single-point and multi-point short-strip welding for thin and thin materials of copper, silver, aluminum, and nickel non-ferrous metals. Welding of various shapes such as tabs.

Categories

latest blog

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp