The 35kHz ultrasonic sealing machine is specially designed for thermoplastic fabrics such as nylon fabric, PVC, PU, TPU fabric and non-woven fabric.

Item No.:

HS-S35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

SilverLead Time:

20

Non-woven Bag Making Machine Ultrasonic Sealing Equipment Constant Output

Description :

Ultrasonic Sewing Machine, also could be called ultrasonic lace machine, ultrasonic sewing machine, is efficient sewing embossing device, use to sewing, welding, cutting and embossing synthetic fiber material. Processing without needle and thread, final products can be water tightness section without rough selvedge and smooth. Widely use to process clothing, toys, food and non-woven materials.

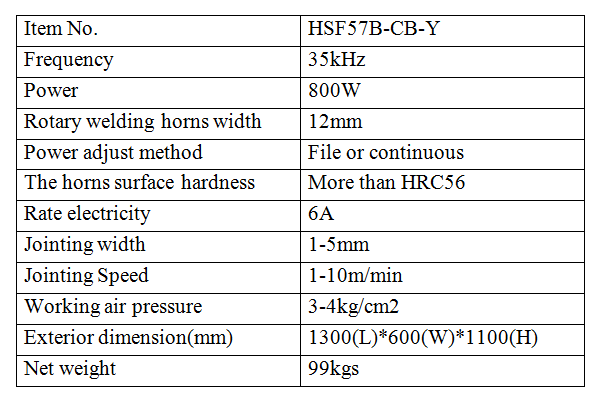

Specification :

Advantages :

1. Stand-alone system enables flexibility and tight turns in sealing and/or cutting, and provides unobstructed view of fabric in the processing area;

2. Two-position foot switch facilitates operation – first position raises and engages the rotary wheel, applying force to the material being processed; second position activates ultrasonic and wheel rotation;

3. Operator-selectable maximum operator speed enables operator to set maximum feed speed at the fully depressed foot switch position setting;

4. Designed for operator safety – no needles or other moving parts above the work surface;

5. Operator controls conveniently located on control panel, including pneumatic pressure regulator; on/off switch; power on indicator; and nip control;

6. Various sealing patterns available, including standard single stitch, right or left slant, and zigzag; custom-designed patterns also available at additional fee.

Application :

Non-woven bags, gift bags, cosmetic bags, net bundles, non-woven computer sets, TV sets, air-conditioning sets, washing machine sets, dust cover sets, pillowcases, shoe covers, high-grade non-woven mattresses, hotels Textile disposables. Non-woven saunas include: sauna suits, bathrobes, bath pants, paper underwear - and other environmentally friendly non-woven products.

FAQ :

1. Q: When the aircut is found, the current is large, the amplitude is large, and there is a screaming phenomenon.

A: Adjust the frequency modulation coil until the current and amplitude are simultaneously adjusted to the lowest point, and then adjust the amplitude to 1% higher than the original amplitude;

When the adjustment does not solve the problem, judge that the vibrating section and the HORN are damaged.

2. Q: The current of the vibration box exceeds the above table.

A: Check the HORN, horn and transducer for cracks. If there is crack, it means the vibrator is broken. If no crack is found, remove the HORN and adjust to resonance. This is normal. At the time, it indicates that HORN is bad.

Workshop :

CE :

Shipping :

Payment :

Previous :

Rotary Welding Ultrasonic Sewing Machine For TPU Waterproof MaterialNext :

35kHz 800watt Ultrasonic Rotary Welding Machine Sewing Machine Parts for Chemical Fiber FabricIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp