Today ultrasonic welding is used in every industry that processes plastics. Most common uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging industries.Conforming to the spirit of "Service First", ALTRASONIC provides lifetime maintenance to its products for as long as they are used by customers.

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Silver, BuleShipping port:

Shanghai or Ningbo

Ultrasonic Riveting Wedling For PE HDPE PVC

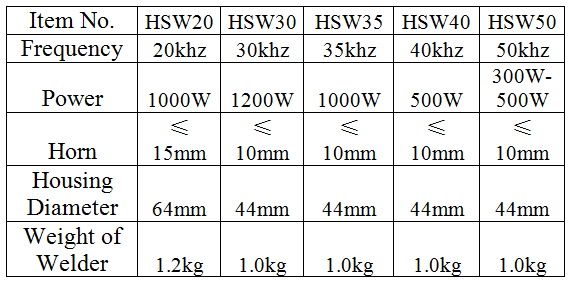

Specification:

Description:

Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

Advantage:

1. Ultrasonic welding can be applied to a diversity of combination of the material welding, It can not applied for semiconductor materials such as high temperature caused by the pollution and the operation, It is easy to weld the heat conductivity and high conductivity materials like gold , silver , copper , aluminum , etc .

2. The consumption power is small , only for the resistance spot welding 5% left and right sides, weld deformation less than 3-5% , solder joint strength and strength the stability by an average of about 15-20% , on the surface of cleanliness requirements is not high.

3. Ultrasonic welding process is widely used in the microelectronics devices and finishing technology, the most successful application is the integrated circuit element of interconnection and it is used in the electronic aerospace electrical packaging plastic industries .

4. Ultrasonic welding process successfully joins many dissimilar-materials combinations, It welds without filler metals or gases, It is fast and easily automated, Because ultrasonic welding does not require the connective bolts or soldering materials to bind two pieces together, it saves on the manufacturing & production costs.

5. Ultrasonic welding process is ideal because it creates the reliable bonds without introducing any impurities or thermal distortion to the components being joined, The ultrasonic weld dries rapidly because there are no adhesives or solvents to dry and there is no need for the materials to cure.

6. Ultrasonic Welding process offers the clean exteriors of welded parts, The potential manpower savings, The absence of drying time in the jig , the gas tight and it has completely stable, possibility of welding in the presence of the foreign bodies such as the powders and the liquids that are incompatible using any other conventional assembly processes .

Application:

1. Auto parts: bumpers, air filters, car audios, foot pads, door panels, clutch forks

2. Electric products: humidifiers, chargers, storage battery, telephones, sockets, flash discs

3. Medical products: leucocyte filters, accurate liquid medicine filters, blood plasma separating cups

4. Packaging and clothing: valve bags, paper cups, dairy food packing cases, bag belts, zippers

5. Stationery and toys: ink boxes, file folders, name card holders, albums

Previous :

Ultrasonic Spot Welding 35kHz Riveting Plastic Assembly for Welding Automotive PartsNext :

35kHz Ultrasonic Spot Welding For Silencer In Auto PartsIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp