The excellent ultrasonic control technology can ensure the stability of long-term machining. Frequency scanning and power setting can be completed automatically by controller to improve productivity.

Item No.:

HS-M20Payment:

T/T, PayPal, West UnionProduct origin:

ChinaColor:

Silver and GreenShipping port:

Shanghai or NingboLead Time:

45

Ultrasonic Grinding Connect CNC Processing Semiconductor Ceramics

Specification:

Item No.: HS-M20

Frequency: 20kHz

Power: 500Watt

Speed: 20,000RPM

Amplitude: 10um or more

Diameter of Horn:

Milling: Φ1-Ф13mm

Drilling:Ф2-Ф6mm

Spindle: BT40 / BT50 / R8 / HSK63 / ISO / CAT

(Special spindles are made per request.)

Description:

Rotary ultrasonic-assisted machining is a new processing technology obtained by combining traditional machining and ultrasonic machining. Compared with traditional machining, rotary ultrasonic assisted machining has the advantages of low cutting force, low cutting heat, high machining accuracy and high processing efficiency, and is widely used in hard and brittle materials such as single crystal silicon, engineering ceramics, cemented carbide, and composite materials such as carbon fiber. Processing, has broad application prospects.

Advantage:

1. The excellent ultrasonic control technology can ensure the stability of long-term machining. Frequency scanning and power setting can be completed automatically by controller to improve productivity.

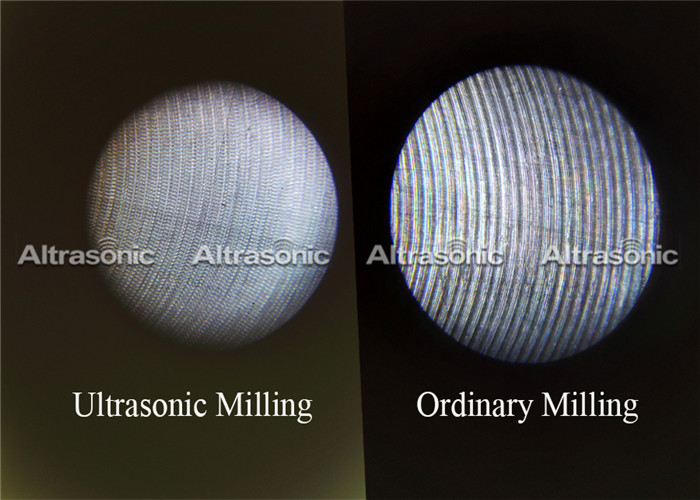

2. Periodical tool axial vibration decreases the cutting resistance and increases the surface quality.

3. Modular design, equipped with high speed spindle, allows high efficiency machining.

4. Coolant through spindle is available for chip disposal and to reduce tool wear caused by temperature rise and cutting resistance.

5. The roughness of metal cutting surface is around Ra 0.2 µm, it reduces the polishing procedure and achieves the quality of final finishing.

6. The ultrasonic machining technology not only reduces chipping but also has the ability to process micropore machining on hard and brittle materials.

Application:

1.Tight-tolerance round thru-holes for semiconductor processing equipment components

2.Micromachined and micro-structured glass wafers for microelectromechanical systems (MEMS) applications

3.High-aspect ratio thru-vias; 60-to-1 aspect ratios are possible in glass and advanced material

4.Features machined into Ceramic Matrix Composites for Aerospace manufacturing

Previous :

precision milling process ultrasonic auxiliary system ultrasonic tool holder BT30/BT40/BT50Next :

Enhanced Procision Ultrasonic Machining in Mould IndustryIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp