By using high-frequency, the sound wave is transmitted from the welding head to the welding surface of the workpiece, and the working object molecules are instantaneously rubbed to reach the melting point of the plastic, thereby completing the rapid dissolution of the solid material and completing the welding.

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

CustomizedProduct weight:

1000gShipping port:

Ningbo or Shanghai35kHz Ultrasonic Welding System of Automatic Machine Tool

Description:

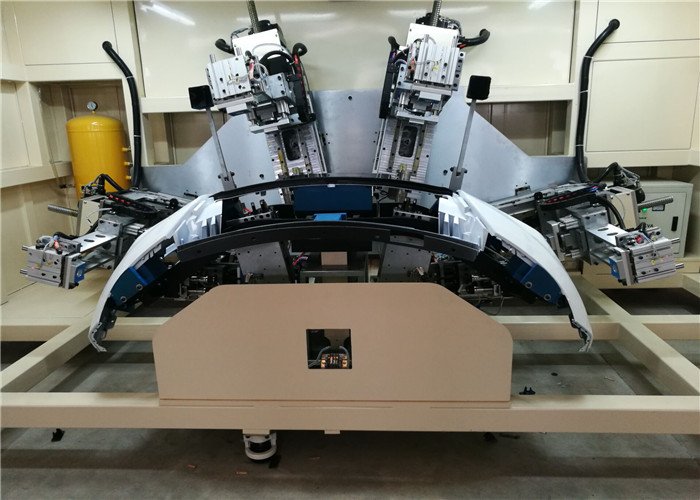

With the popularization of ultrasonic welding technology, the traditional ultrasonic welding system alone can't meet the mass welding task. Full automatic multi-head ultrasonic weling machine belongs to multi-station ultrasonic welding machine, which can be used for multiplw welding at one time or large area overall welding at one time.

Principle of Ultrasonic Spot Welder:

When the ultrasonic role in the thermoplastic plastic contact surface, it will generate tens of thousands of times per second, high frequency vibration, this high-frequency vibration, ultrasonic energy through the ultrasonic wave transmitted to the mold to ultrasonic welding material surface, it will produce high-temperature materials. Plastic contact surface resulting in rapid melting, coupled with stress, it blend and coagulation, so that to achieve the purpose of ultrasonic welding.

Specification:

Item No.

HSW28

HSW30

HSW35

HSW40

HSW50

Frequency

28kHz

30kHz

35kHz

40kHz

50kHz

Power

1000W

1200W

1000W

500W

300W-500W

Horn

≤ 12mm

≤ 10mm

≤ 10mm

≤ 10mm

≤ 10mm

Housing diameter

44mm

44mm

44mm

44mm

44mm

Weight of welder

1.0kg

1.0kg

1.0kg

1.0kg

1.0kg

Advantage:

1. Digital Generator, equipped with a professional cooling system to improve the stability of the equipment.

2. The hand-held ultrasonic welding gun can replace different ultrasonic welding heads according to different welding requirements.

3. High-tech surface technology treatment, corrosion resistance, impact resistance, no rust. With successful high-quality transducers, the power is nearly double of similar products on the market.

4. The professional anti-shock technology is more lightweight and more precise.

5. Low noise, environmentally friendly working environment.

Application:

| Toy industry | Plastic toys, water guns, aquatic life video game, children dolls, plastic gifts, etc |

| Electronic products | Recording, audio tape boxes and core wheel, disk enclosure, remote control, etc |

| Household appliances | lectronic clock, electric trumpeter hairdryer, steam iron water tank, etc |

| Stationery | aquarium ruler, the raphe folder and shell, pen stand, cosmetics box shell, etc |

| Car, motorcycle | Battery, front corner lamp, rear tail light, instrument, reflectors, etc |

| The packaging industry | Hollow crate welding, ziplock welded |

Precautions:

1. The equipment has been debugged to the best condition before leaving the factory. Do not disassemble the torch housing or the power supply housing when using it.

2. The equipment must be kept clean during use to prevent dust and moisture from entering.

3. The device is designed with a micro switch on the outer casing and the handle. It can be operated by touching the switch during use. Do not work for a long time without any load, otherwise the equipment may be damaged.

Previous :

High Frequency Ultrasonic System in Medical SurgeryNext :

Seamless Hand-held Ultrasonic Spot Welding Equipment for shoesIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp