Nose pin group is widely used in weaving enterprises such as non-woven masks.

Payment:

T/T, Paypal, Western UnionPrice:

$1200/PCProduct origin:

ChinaColor:

Black or SliverShipping port:

Shanghai or NingboLead Time:

5

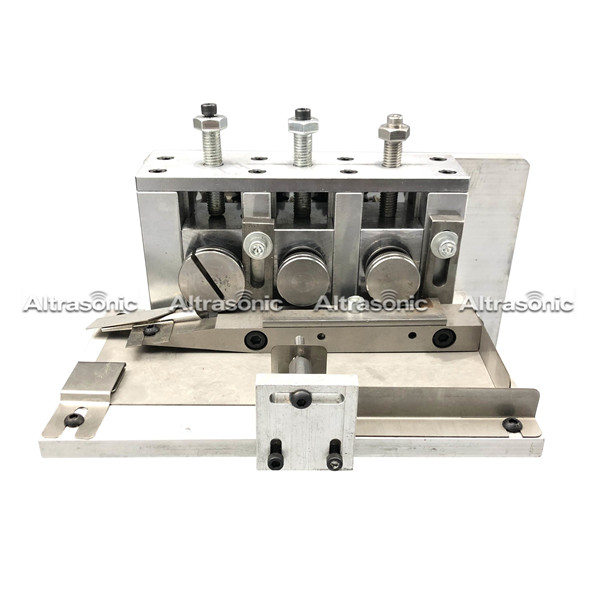

3 ply Surgery Mask Making Machine Components for Cutting Nose Pin

Description:

The nose pin feeding mechanism of the mask machine is used to feed the metal nose pin of the mask. The mechanism includes metal strip straightening mechanism, feeding, cutting mechanism, etc. The metal strip is clamped and fed forward by two pairs of intermeshing rollers, and a roller cutter is arranged at the end to cut the metal strip to a fixed length.

Product List:

Roller

Glue roll

Rubber wheel

Gear

Nose bridge group

Bending group

Production Process:

1. Press the edges and the bridge of the nose, and initially press.

2. Secondary pressure.

3. Cut off the edge strips.

4. Flanging forming is to wrap the sides of the mask.

Production Accuracy:

Geometric shape accuracy:

The geometric shape accuracy refers to the accuracy of the geometric shapes such as the surfaces or axes of the components, such as whether the line is straight, whether the surface is flat, whether the normal cross section of the cylinder is round, etc. The allowable range of variation is represented by "shape and position tolerance". The smaller the shape and position tolerance number, the higher the shape accuracy.

Dimensional accuracy:

Dimensional accuracy refers to the degree of size of the part after processing, expressed by "dimension tolerance". When the dimensions of the parts are the same, the higher the accuracy, the smaller the tolerance number.

Position accuracy:

Position accuracy refers to the accuracy of the mutual position between the various surfaces of the component, such as whether the two planes are parallel, perpendicular, and whether the two axes are coaxial, etc., expressed by "position tolerance".

Workshop:

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Ultrasonic Spot Welding Equipment Weld Tool Mold Round Horn For Ultrasonic Sewing MachineNext :

Automatic Nose Pin Parts of Surgery Mask Making MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp