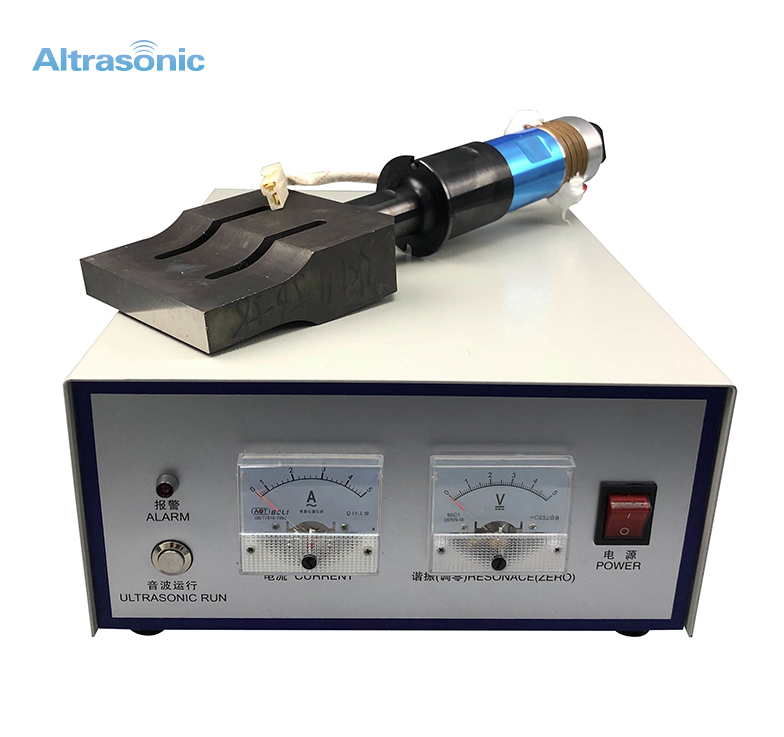

Ultrasonic Plastic Welder

Ultrasonic plastic welding machine, which is a welding equipment developed and designed by ultrasonic plastic welding equipment in the field of plastic welding, is referred to as ultrasonic plastic welding machine in the industry. Ultrasonic welding equipment is a high-tech technology for welding cooked plastic products. All kinds of cooked plastic plastic parts can be welded by ultrasonic welding. When welding plastic products, do not add any adhesive, filler or solvent, nor consume a lot of heat sources. It has the advantages of simple operation, fast welding speed, high welding strength, high production efficiency, etc. Therefore, ultrasonic welding technology is more and more widely used.

Working principle:

When the ultrasonic wave acts on the contact surface of thermoplastic plastic, it will produce tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper weldment. Because the sound resistance at the interface of the two welding areas is large, local high temperature will be generated. And because of the poor thermal conductivity of the plastic, it can not be distributed in time for a while, and it is gathered in the welding area, resulting in the rapid melting of the contact surface of the two plastics, and after adding a certain pressure, it will be fused into one. When the ultrasonic stops working, let the pressure continue for several seconds to solidify and form a solid molecular chain to achieve the purpose of welding. The welding strength can be close to the strength of raw materials. The quality of ultrasonic plastic welding depends on the amplitude of the transducer welding head, the applied pressure and the welding time. The welding time and the welding head pressure can be adjusted, and the amplitude is determined by the transducer and the horn. There is an appropriate value for the interaction of these three quantities. When the energy exceeds the appropriate value, the melting amount of plastic is large, and the weldment is easy to deform; If the energy is small, it is not easy to weld firmly, and the pressure should not be too large. The optimum pressure is the product of the side length of the welding part and the optimum pressure per 1mm of the edge.

Advantages:

1. Fast welding speed, high welding strength and good sealing;

2. It replaces the traditional welding and bonding process, with low cost, clean and pollution-free, and will not damage the workpiece;

3. The welding process is stable, and all welding parameters can be tracked and monitored through the software system. Once a fault is found, it is easy to remove and maintain.

Welding method:

1. Fusion welding method: ultrasonic vibration transmits ultrasonic wave to the weldment along with the welding head. Because of the large sound resistance at the two weldments, the local high-temperature part interface melting occurs. Under certain pressure, make the two weldments achieve beautiful, fast and solid welding effect.

2. Embedding (inserting) method: nut or other metal is inserted into plastic workpiece. First, the ultrasonic wave is transmitted to the metal, and the metal object is directly embedded into the molding plastic through high-speed vibration. At the same time, the plastic is melted, and the embedding is completed after curing.

3. Riveting method: To join metal and plastic or two pieces of plastic with different properties, ultrasonic riveting method can be used to make the weldment not easy to embrittle, beautiful and solid.

4. Spot welding method: use small welding head to weld two large plastic products separately, or press the whole row of tooth-shaped welding head directly on two plastic parts to achieve the effect of spot welding.

5. Forming method: use ultrasonic wave to melt the plastic workpiece into shape instantly. When the plastic solidifies, it can make the metal or other plastic materials firm.

6. Cutting method: using the special design method of welding head and base, when the plastic workpiece is just shot out, it is directly pressed on the plastic branch, and the cutting effect is achieved through ultrasonic transmission.

We have hand-held spot welding equipment and automatic welding equipment. Hand-held spot welding equipment, with small size and beautiful appearance, is suitable for welding in local areas, with small scope of action and can improve welding efficiency. Plastic welding equipment is suitable for assembly line work with a wide range of functions and can realize batch welding.

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp