How to maintain the ultrasonic welding machine

How

to maintain the ultrasonic welding machine

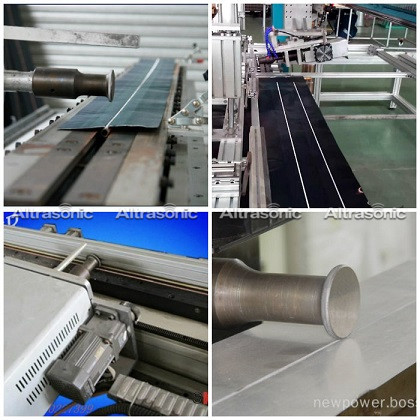

Ultrasonic plastic welding machines have been recognized by more and more factories because of their strong applicability. Traditional manual welding and glue processes will gradually be replaced.

With the advent of the Industrial 4.0 era, intelligent manufacturing entered the factory, and AI intelligent ultrasonic welding equipment was born. For different styles and types of ultrasonic plastic welding machines,

How to carry out maintenance? What features should the ultrasonic welder maintain? Is it necessary for professional personnel to maintain and maintain plastic welding equipment? Let's take a look.

Daily maintenance knowledge of ultrasonic plastic welding machines.

Maintenance

of ultrasonic plastic welding machine: equipment maintenance, equipment testing

and equipment repair.

Maintenance of ultrasonic welding machine:

Keep

ultrasonic plastic welding equipment clean, tidy, well lubricated and safe to

operate. This includes tightening loose fasteners in time, adjusting the

clearance of the moving parts, and so on. That is, "clean, lubricate,

tighten, adjust, anti-corrosion" cross-operation method. Practice has

proved that the service life of the equipment depends largely on the daily maintenance

of the ultrasonic welding machine.

Maintenance

is divided into daily maintenance, primary maintenance, secondary maintenance

and tertiary maintenance according to the size and difficulty of the workload.

Daily

maintenance: Also known as routine maintenance, the

main content is to clean, lubricate, fasten parts that are easy to loosen, and

check the integrity of parts. Most of this type of maintenance is external to

the equipment.

Primary

maintenance: The main content is the general

tightening, cleaning, lubrication, fastening, and some need to be adjusted.

Daily maintenance and first-level maintenance can be completed by the frontline

operator.

Secondary

maintenance: The main content is internal

cleaning, lubrication, partial disassembly inspection and adjustment.

Three-level

maintenance: It is mainly to check and adjust the

main part of the equipment, and replace the parts that meet the specified wear

limit when necessary. In addition, the wear and tear of the main components is

measured, identified and recorded. Secondary maintenance and tertiary

maintenance are required for the operator to complete the training.

In

addition to ultrasonic welding machines, daily maintenance of rotary friction

welding machines, heat welding machines, hot plate welding machines, and

ultrasonic cutting equipment is the basis. In the actual production and

equipment maintenance process, according to the machine's production process,

structural complexity, structural complexity, etc. to develop good machine

operating practices and maintenance habits.

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp