Our offered drilling machine is manufactured using premium quality components and modern technology in line with industry standards. Furthermore, this drilling machine is available in different technical specifications and sizes as per the requirements of the clients.

Item No.:

HSM20Product origin:

ChinaProduct weight:

13kg

Ultrasonic Turning, Drilling Ultrasonic Drawing Die Procession

Description:

With our rich industry experience, we manufacture an extensive range of Ultrasonic Drilling Machine that is widely used drilling purpose. Our offered drilling machine is manufactured using premium quality components and modern technology in line with industry standards. Furthermore, this drilling machine is available in different technical specifications and sizes as per the requirements of the clients. Appreciated for its reliability, high strength and durability, this drilling machine is demanded in the market.

Features:

Specification:

| Frequency | 20Khz / 40Khz |

| Output Power | 500W / 1000W |

| Voltage | 220 V / 110V |

| Switch | Handle or foot switch |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weight | 30 KG ( Determined by the size of the horn ) |

| Generator | Digital Generator |

Technical Parameters:

Product shape: BT/ HSK/ ISO/R8 series tool holder

Working frequency: 15-21KHz;

Resonance point amplitude: 10um or more;

Speed: 3000 r / min or less

Matching tool: carbide end mill head Φ2-Φ13; disk cutter Φ50;

Power: 500W/1000W

Function:

Ultrasonic vibration during the machining cycle to accomplish rapid material removal, improved surface quality, and maximized tool life.

Other advantages of this process include a superior surface finish and low tool pressure.

Ultrasonic machining provides a number of advantages compared to conventional machining techniques.

Both conductive and nonconductive materials can be machined, complex three-dimensional contours can be machined as quickly as simple shapes.

Additionally, the process does not produce a heat-affected zone or cause any chemical/electrical alterations on the workpiece surface, a shallow, compressive residual stress generated on the workpiece surface can increase the high-cycle fatigue strength of the machined part.

Previous :

20khz 2000W Spindle Ultrasonic with HSK63 Connector for DrillingNext :

bone ultrasonic drilling machineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

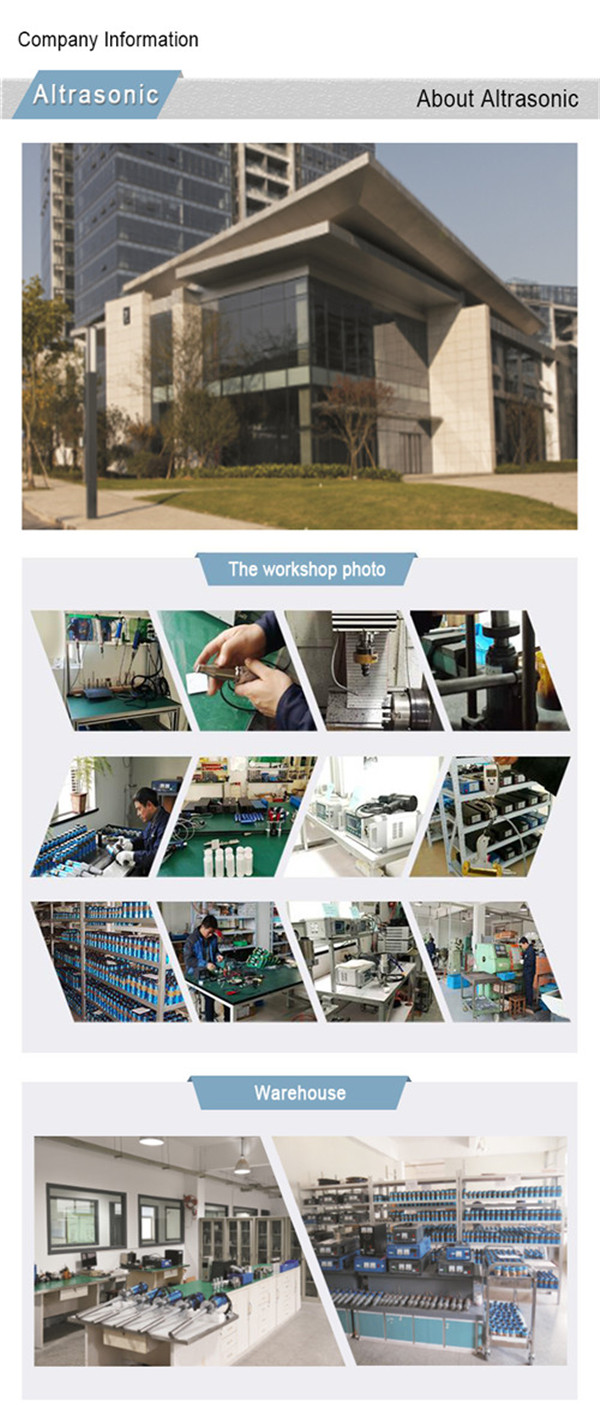

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp