Ultrasonic spot welding machine is designed for auto parts single weld. The handheld shape brings much more convenience in using.

Item No.:

HS-GW35Product origin:

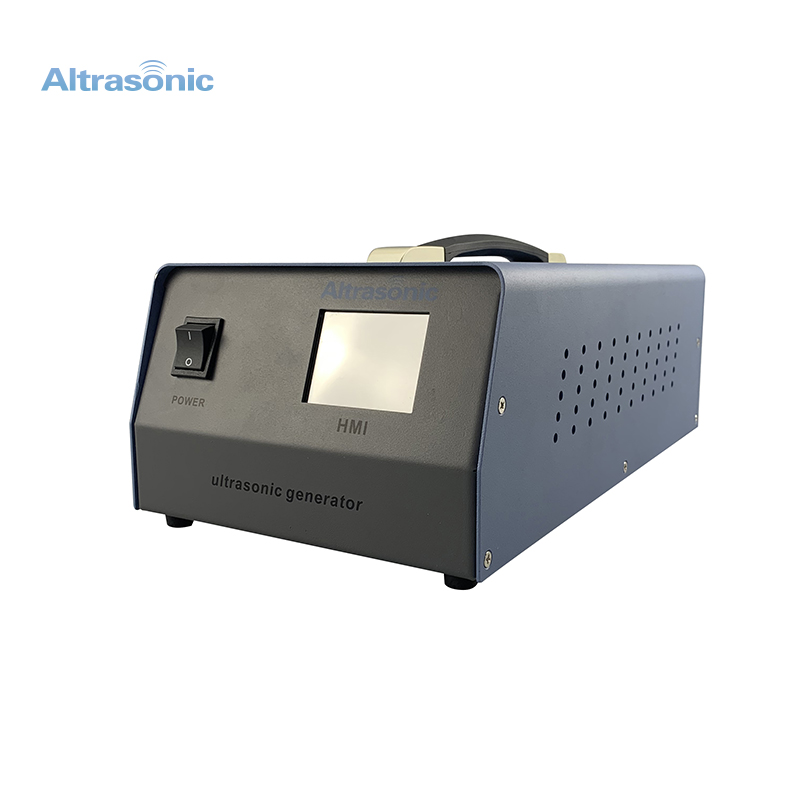

ChinaUltrasonic Spot Welding Machine for Plastic Assembly with 35kHz

Description:

The ultrasonic waves vibrate 10's of thousands of times per-second. This oscillation is transferred to a contact surface that is directly in contact with the plastic parts. Since the boundary of the welding area has a large acoustic impedance, it produces high temperatures. Plastic is a pretty poor conductor of heat and can't dissipate the heat before it changes the state of the plastic from solid to liquid. With a bit of pressure applied, this makes the two parts blend together as if they are a single piece of plastic. Once the ultrasonic signal is stopped, the parts become solid again. This is the magic that creates a weld between the two parts that is clean and very strong. The weld will have a strength that is close to that of the raw materials being formed together in an injection molding process.

Application :

Auto parts: bumpers, air filters, car audios, foot pads, door panels, clutch forks;

Electric products: humidifiers, chargers, storage battery, telephones, sockets, flash discs;

Medical products: leucocyte filters, accurate liquid medicine filters, blood plasma separating cups;

Packaging and clothing: valve bags, paper cups, dairy food packing cases, bag belts, zippers;

Stationery and toys: ink boxes, file folders, name card holders, albums.

Specifications:

| Item No. | HS-GW35 |

| Frequency | 35kHz |

| Max power | 1000W |

| Horn diameter | ≤20mm |

| Housing diameter | 44mm |

| Weight of welder | 8kg |

Advantage:

1. Ultrasonic is the fastest, most repeatable and economical assembly method available to the industry today.

2. With ultrasonic, most thermoplastics can be assembled without heat, mechanical fasteners, or hazardous consumables such as adhesives or solvents.

3. Ultrasonic can join parts - small or large, simple or complex - with lower reject rates than any other method.

4. Using ultrasonic, labor - both as a skill factor and as a time factor - is significantly reduced. And since the equipment can readily be automated, any non-technical operator can be trained in minutes to produce high volume, high integrity assemblies.

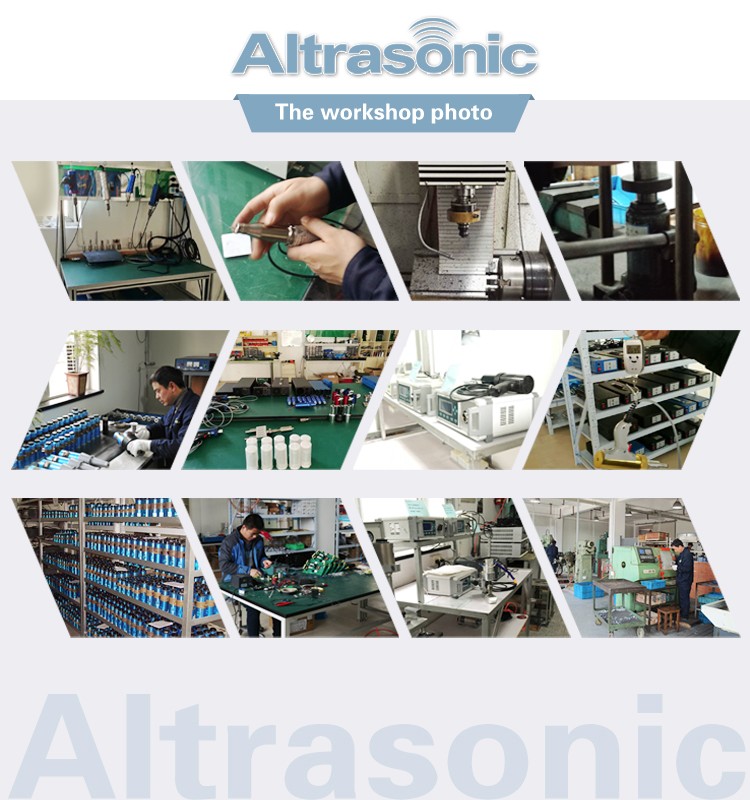

Workshop:

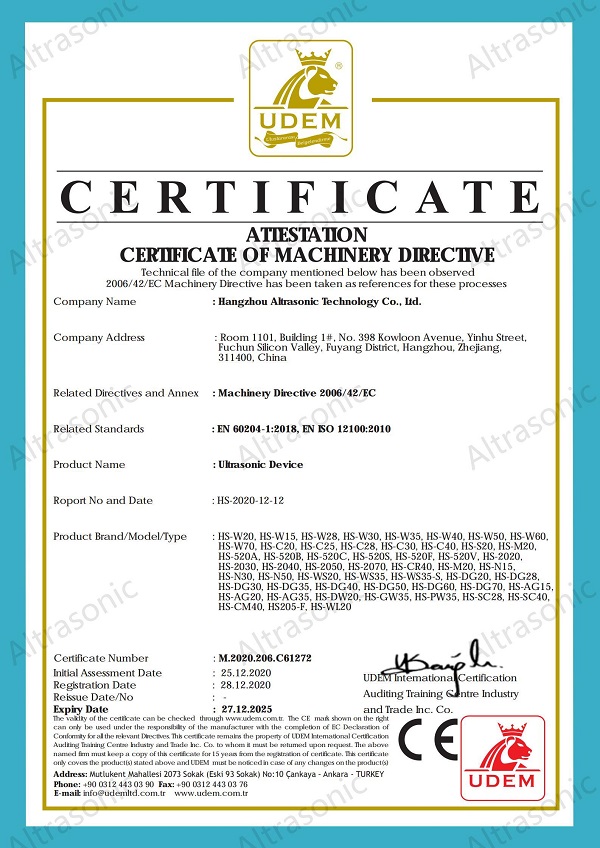

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Ultrasonic Spot Welder System 35kHz Puncture Welder with High Power Auto / ManualNext :

Ultrasonic Plastic Assembly for 35kHz 1000W Spot Welding EquipmentIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp