A horn analyzer is an instrument used to determine the resonance and anti-resonance frequencies of ultrasonic parts such as transducers, sonotrodes and acoustic sets, which are used in ultrasonic welding, cutting, cleaning and other industrial applications. In addition, digital horn analyzers are able to determine the electrical impedance of piezoelectric materials.

Product weight:

10KgUltrasonic Horn Analyzer Power Ultrasonic Transducers, Horns (Sonotrodes) and Correlated Devices

Description:

A horn analyzer is an instrument used to determine the resonance and anti-resonance frequencies of ultrasonic parts such as transducers, sonotrodes and acoustic sets, which are used in ultrasonic welding, cutting, cleaning and other industrial applications. In addition, digital horn analyzers are able to determine the electrical impedance of piezoelectric materials.

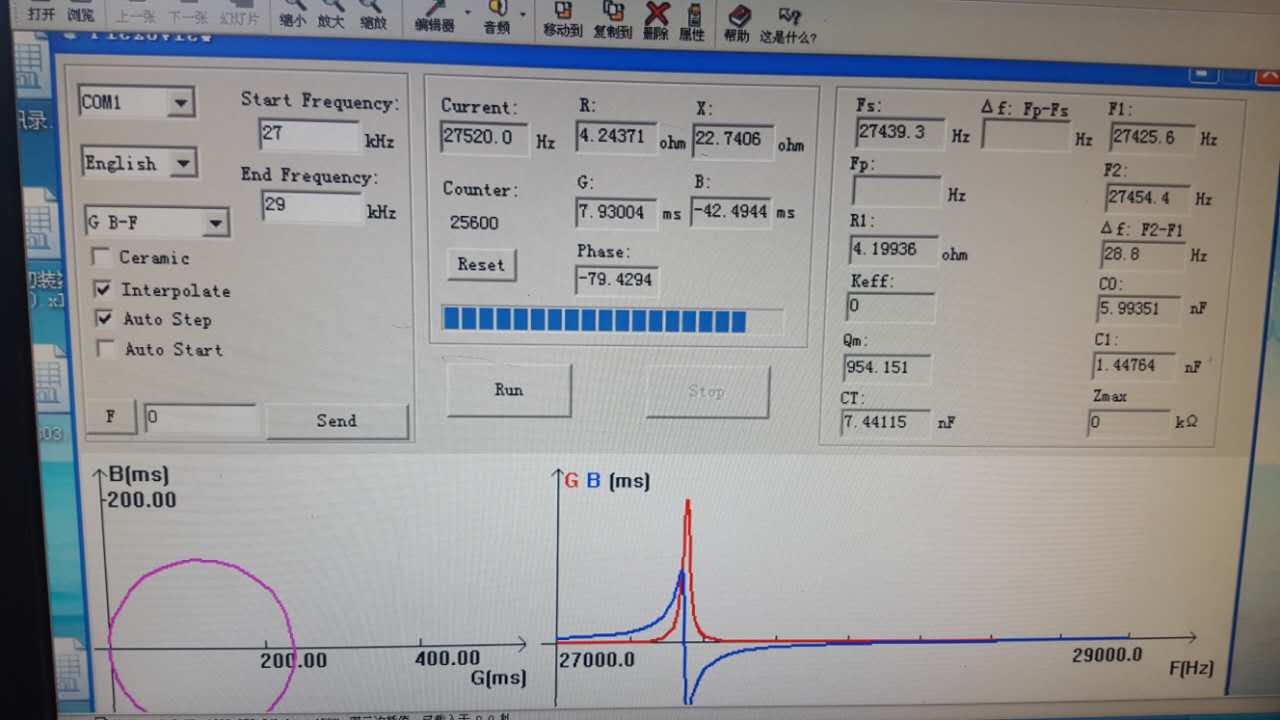

A digital horn analyzer performs a frequency sweep while monitoring the current flowing through the device under test, in order to detect the resonance and anti-resonance frequencies and their respective electrical impedances. The anti-resonance is the frequency at which the current encounters maximum impedance, and the resonance is the frequency of minimum impedance.

In analog microampere-meter-based horn analyzers, the user identifies the frequencies manually, using the meter to detect the points of minimum and maximum current while sweeping the driving frequency. In digital analyzers, frequency detection and impedance calculation are performed automatically through embedded software.

Impedance analyzers can be used as advanced horn analyzers, but are not usually a cost-effective alternative for everyday industrial demands, due to their higher cost, larger size and greater complexity.

Advantages and benefits:

·• Practicality and ease of use. No need for ultrasonic expertise.

·• Allows the quality control of ultrasonic transducers reducing technical assistance.

·• Makes fast and accurate manufacturing of sonotrodes possible.

·• Affordable cost.

·• Reduces ultrasonic equipment maintenance costs because it allows preventive maintenance.

Usage guidelines:

To operate, the TRZ Horn Analyzer requires only a power outlet of 127 or 220 VAC (50-60 Hz). After connected, simply connect the transducer to the test probe, select the type of transducer and order the measure. The result is shown on a display with backlight and high contrast. To repeat the test, simply press the "Start" button again.

Types of transducers and the equipment characteristics:

The equipment has 27 pre-configured transducers, 09 of welding system, 16 of cleaning and 02 of dental scalers. Additional settings can be incorporated according to the customer's needs.

For the tuning of sonotrodes it is necessary to couple it with a transducer.

The TRZ Horn Analyzer is also suitable for the determining of the impedance of other piezoelectric devices such as sensors, accelerometers and actuators.

Features of the instrument for ranges from 5 to 100 kHz and from 50 Ω to 20 KΩ

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp