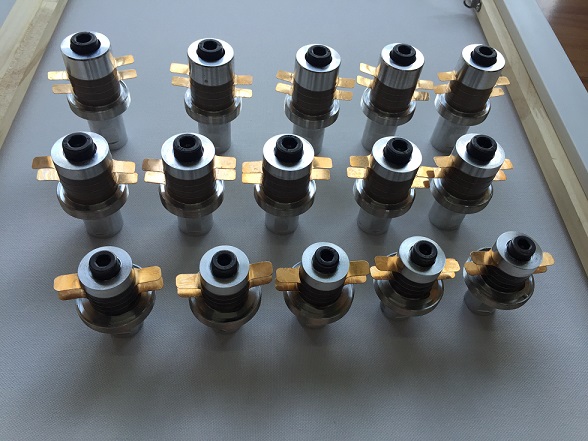

30khz 800W Ultrasonic Converter PZT8 with M40*1 Thread for Welding Machine / Cutting Machine

Product origin:

ChinaMin order:

2

Specifications:

Model |

3030-4Z |

Frequency |

30 khz |

Output power |

800 watt |

Joint bolt |

custom - made |

Ceramic disc Diameter |

30 mm |

Quantity of Ceramic discs |

4 pcs |

Capacitance |

6.2-6.9nf |

Amplitude |

8 um |

Application |

welding machine / cutting machine |

Description:

The 30khz 800W Ultrasonic Converter PZT8 with M40*1 Thread is applied to different type ultrasonic spot welding machine, cutting machine and sealing machine. And can be connected with different type horn.

The transducer converts high-frequency electrical energy into high-frequency mechanical vibrations. And it contains several piezoelectric ceramic discs sandwiched under pressure between two metal blocks. Between each disc is a thin metal plate, which forms the electrode. When a sinusoidal electrical signal is fed to the transducer via the electrodes, the discs expand and contract, producing axial vibrations.

Applied Industries :

automobile industry, electric industry, medical industry, household appliance industry, non woven fabric clothing,

Competitive Advantage:

1. Titanium, aluminum, steel materials of horn optional.

2. Once assembled, the transducers are aged before testing and final assembly. The properties of piezoelectric materials can change with time and pressure, so a bit of time on the shelf prior to testing will identify nonconforming material.

3. One by one testing to ensure that each transducer performance are excellent.

4. In good heat resistance, can be used in a wide range of temperature with long life and high reliability.

Previous :

30khz ultrasonic converter 4 pieces PZT ceramic welding transducerNext :

3030-4Z 700W Ultrasonic Transducer M10 ConnectedIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp