Ultrasonic welding uses high frequency, low amplitude vibration to create heat between the two materials being joined. When used with plastics, it is important that both materials are made from similar amorphous polymers and have near equivalent melting points. The thermal rise in the bonded area is produced by the absorption of vibrations and the friction of the surfaces of the parts.

Today ultrasonic welding is used in every industry that processes plastics. Most common uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging industries.Conforming to the spirit of "Service First", ALTRASONIC provides lifetime maintenance to its products for as long as they are used by customers.

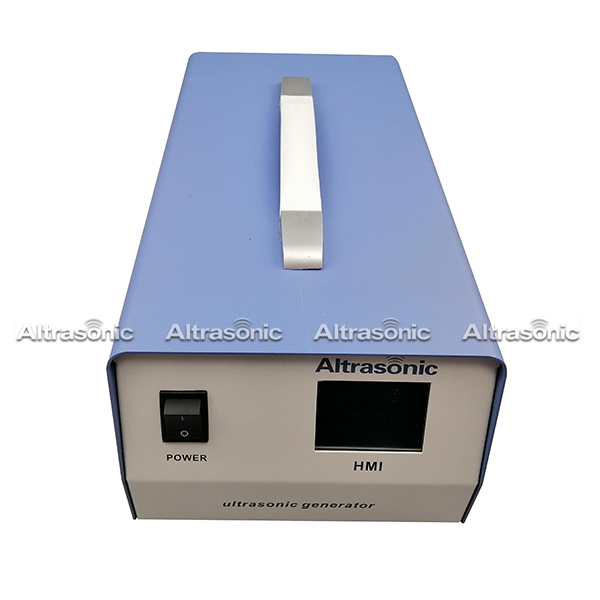

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Blue and SilverShipping port:

Ningbo or Shanghai

Handheld 35kHz Ultrasonic Assembly Welding Machine for Thermoplastic Material

Description:

Ultrasonic welding uses high frequency, low amplitude vibration to create heat between the two materials being joined. When used with plastics, it is important that both materials are made from similar amorphous polymers and have near equivalent melting points. The thermal rise in the bonded area is produced by the absorption of vibrations and the friction of the surfaces of the parts. The material plasticizes locally, creating an insoluble connection between both parts within a very short period of time.

Application :

Ultrasonic plastic welding is also utilized in the medical industry, primarily because it doesn’t introduce contaminants. Items such as anesthesia filters, blood filters, IV catheters, dialysis tubes and face masks can be made using ultrasonic plastic welding. Another important application in the medical field is the construction of such textile wear as hospital gowns, surgery garments, and transdermal patches, just to name a few. These items can be sewn and sealed using ultrasonic plastic welding to avoid and reduce the risk of infection.

Ultrasonic plastic welding is frequently used in the packaging industry. Everyday items, ranging from butane lighters to food containers, are created or packaged with ultrasonic plastic welding. Ultrasonic plastic welding is also found in the packaging of dangerous explosives, such as fireworks or dangerous chemicals. These items can’t be subjected to high temperatures, yet must be contained in an airtight container that can withstand stress and high pressure.

The food industry relies on ultrasonic plastic welding because it’s fast and sanitary while producing airtight seals. Milk and juice containers are prime examples of products sealed with an ultrasonic plastic welding machine. To complete the task, paper cartons are coated with sheer layers of plastic that are then welded together.

Specifications:

| Item No. | HSW20 | HSW30 | HSW35 | HSW40 | HSW60 |

| Frequency | 20kHz | 30kHz | 35kHz | 40kHz | 60kHz |

| Max power | 1000W | 1200W | 1000W | 500W | 500W |

| Horn | ≤12mm | ≤10mm | ≤10mm | ≤10mm | ≤10mm |

| Housing diameter | 44mm | 44mm | 44mm | 44mm | 44mm |

| Weight of welder | 1.0kg | 1.0kg | 1.0kg | 1.0kg | 1.0kg |

Advantage:

1. Lightweight

Thanks to their plastic housing, the ultrasonic hand welding units are extremely light yet also robust.

2. Ergonomic shape

The weight of the ultrasonic hand welding guns is perfectly balanced thanks to their design, making them feel even lighter to handle as a result.

3. Service friendly

The converter can be changed over in no time.

4. Convenient working

Operating the hand unit is simple, safe, comfortable and intuitive.

5. Air cooling

Air cooling for the sonotrode and the converter is pre-integrated in the hand unit and should be used as required.

Previous :

35kHz Ultrasonic Welding Equipment for Automotive Parts Assemble TechnologyNext :

Ultrasonic Plastic Welding Equipment for 35kHz 1000W Automotive Interior PartsIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp