Today ultrasonic welding is used in every industry that processes plastics. Most common uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging industries.

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

White, BlueShipping port:

Shanghai or Ningbo

35kHz Ultrasonic Assembly in Automated Machine Tool

Description:

Ultrasonic welding of thermoplastics causes local melting of the plastic due to absorption of vibration energy. The vibrations are introduced across the joint to be welded. In metals, Ultrasonic welding occurs due to high-pressure dispersion of surface oxides and local motion of the materials. Although there is heating, it is not enough to melt the base materials. Vibrations are introduced along the joint being welded.

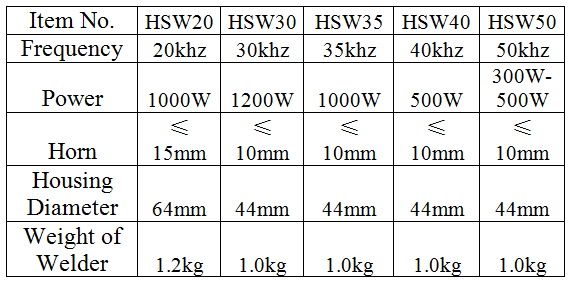

Specification:

Advantage:

Ultrasonic welding offers many advantages to assemblers. It is a fast, efficient, flexible process that offers quick tooling changeover. No warm up or cool down time is necessary, unlike other welding processes, such as hot-plate welding. Ultrasonic welding is an energy efficient cold-working process that does not require elaborate ventilation.

Unlike other joining processes, such as resistance welding, ultrasonic welding does not generate excessive heat that could damage components. The energy efficiency of ultrasonic welding technology appeals to manufacturers that are searching for ways to cut production costs.

Application:

Ultrasonic is not limited to only thermoplastic materials. An ultrasonic assembly process can also be used to install threaded brass inserts into molded plastic bosses; stake plastic bosses over metal plates or printed circuit boards; swage over standing walls to entrap another component; perform continuous line seals on thin films and fabrics; seal the ends of collapsible squeeze tubes; accomplish perimeter seals on clam shell packages; spot weld corrugated plastic sheets in the manufacture of boxes; and much more.

Previous :

40kHz High Power Handheld Ultrasonic Welding DeviceNext :

High Frequency Ultrasonic System in Medical SurgeryIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp