Today

ultrasonic welding is used in every industry that processes plastics. Most common

uses are in the Automotive, Medical, Textile, Food, Plastics, and Packaging

industries. Conforming to the spirit of "Service First", ALTRASONIC

provides lifetime maintenance to its products for as long as they are used by

customers.

Item No.:

HS-W35Payment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Blue and SilverShipping port:

Ningbo or Shanghai

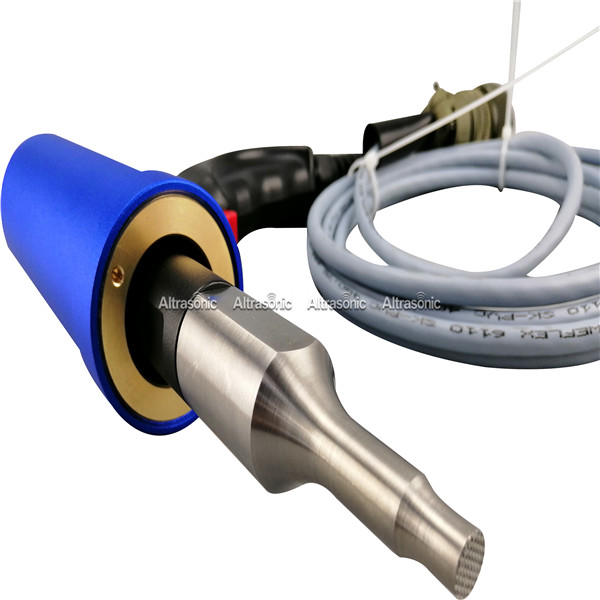

1000Watt Ultrasonic Welding System for Plastic Welding HDPE

Description:

Ultrasonic Welding Machine is the fastest, cheapest, most precise and effective technology used for welding. By using the ultrasounds, a plastic component is welded at a molecular level thanks to the vibrations issued by the sonotrode. The frequencies of the sonotrodes may vary from 20 kHz, 30 kHz, 35 kHz up to 40 kHz, with the amplitude values from 50 to 5 µm.

Vibrations are directed in a specific manner by the use of energy directors with special designed customized following the application requirements. The contact area between the plastic material and the sonotrode is thus welded by the frictional heat generated by the vibrations. The structural design of the parts and the shape of the area to be welded are very important, especially if the sealing and strength requirements have to be met in the process of mass production.

Specification:

|

Item No. |

HSW20 |

HSW30 |

HSW35 |

HSW40 |

HSW60 |

| Frequency |

20kHz |

30kHz |

35kHz |

40kHz |

0kHz |

| Max power |

1000W |

1200W |

1000W |

500W |

500W |

| Horn |

≤12mm |

≤10mm |

≤10mm |

≤10mm |

≤10mm |

| Housing Diameter |

44mm |

44mm |

44mm |

44mm |

44mm |

| Weight of Welder |

1.0kg |

1.0kg |

1.0kg |

1.0kg |

1.0kg |

Advantage:

1. Short welding times (in the order of tenth of seconds)

2. Aesthetic perfection

3. Waterproof welding stable for a long time

4. Labor savings

5. Energy-efficient

6. Flexibility

7. Possibility of welding even in the presence of foreign

bodies

8. Excellent mechanical seal

9. Eliminating the use of solvents and adhesives.

Application:

Simply put, wherever two parts come together and one of them happens to be a thermo plastic resin. Following is a partial list of some of the industries we serve and the typical applications for our process.

• Appliance: Fixtures, hardware, and enclosure assembly, welding of components.

• Automotive: Parts and body components, instrument panels, headlight assemblies, under hood assemblies.

• Cosmetic: Assembly of compacts and other containers, sealing tubes, packaging.

• Electronic/Electrical: Component, connector cable and wire harness assemblies, enclosure cases and instrument faces, audio/video cassette and cartridge, switch assemblies.

• Food: Sealing of pouches, tray containers and fillable fillable tubes; sealing microwavable containers; product packaging.

• Hardware: Product assembly and blister pack packaging.

• Health Care: Product containers and accessories.

• Instrument: Welding and staking case assemblies and face covers.

• Medical: Sterile package sealing; equipment component assembly; syringes and filters.

• Packaging: Welding extruded plastic sheet for boxes/containers, package sealing.

• Textile: Fabric slitting, joining or embossing.

• Toy and Game: Assembly of game elements and product packaging.

Previous :

30Khz Pen Type Ultrasonic Riveting Welder with Metal Shell or Nylon Shell SelectionNext :

Ultrasonic join for all rigid thermoplastics spot weldingIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp