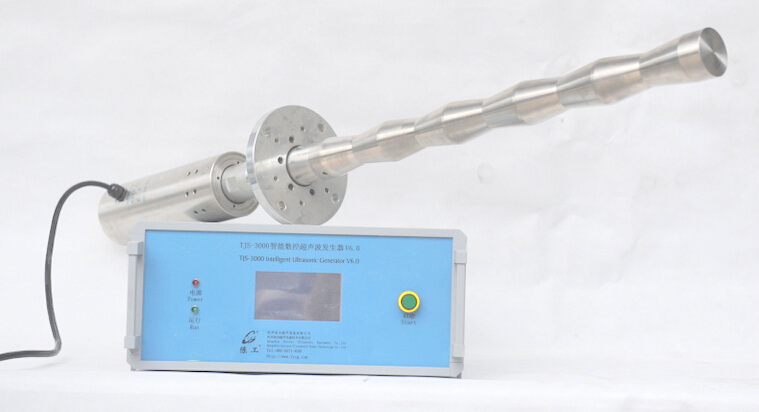

Industrial-scale Ultrasonic Homogenizers With High Ultrasonic Amplitudes

Product weight:

17KgIndustrial-scale Ultrasonic Homogenizers With High Ultrasonic Amplitudes

|

Minimum Order Quantity: |

1 Set |

|

Price: |

|

|

Packaging Details: |

Foam case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

100 Sets/Month |

Quick Detail:

Simple, low-cost design

Low operating costs

High efficiency

Low maintenance

Faster emulsification

The principle of ultrasonic application:

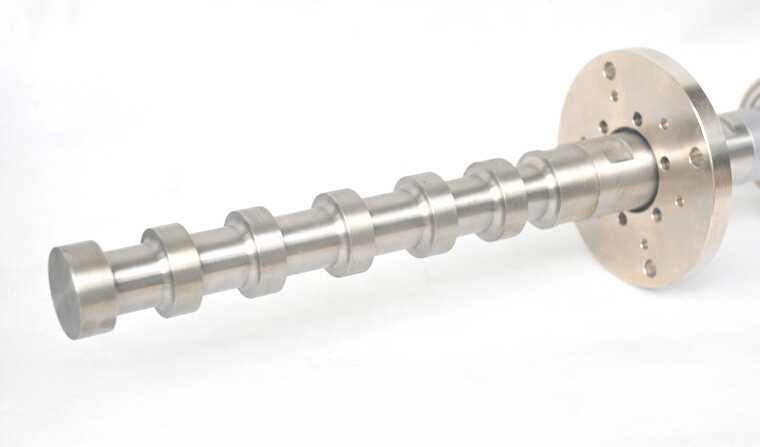

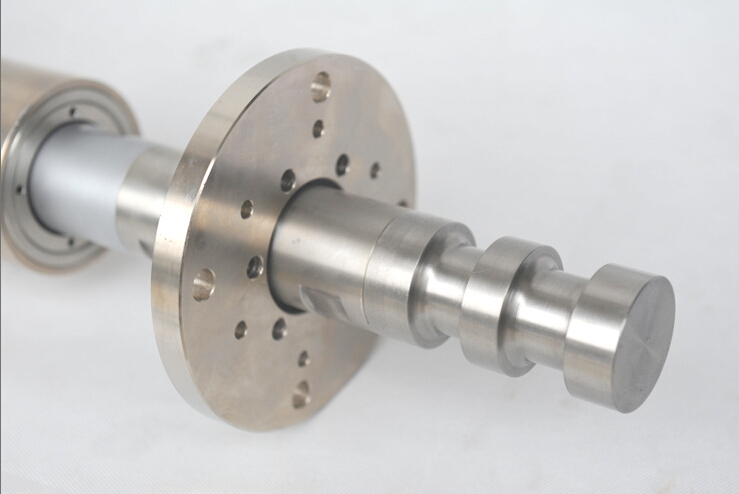

Ultrasound is the use of sonic and ultrasonic homogenizer, rapidly alternating compression and expansion in the face of the principles of object implementation. Material in the role of ultrasound, when the inner half of the expansion in the period, the material was subjected to tension bubbled expansion; when in compression within a half cycle, the contraction of the bubble, when the pressure fluctuated widely and the pressure is lower than the low-pressure when the compressed air bubbles will be a sharp collapse in the feed solution appears a "cavitation" phenomenon, which in turn varies the pressure and the external pressure imbalance disappear in a "cavitation" disappeared instantaneously, liquid caused around very large increase in pressure and temperature, plays a very complex and strong mechanical agitation, to achieve the purpose of homogenization. Meanwhile, in the "cavitation" has on the density difference generated interface will be reflected ultrasonic wave generated intense agitation. According to this principle, an ultrasonic homogenizer by the frequency of 20 ~ 25kHz ultrasonic generator into the feed solution or liquid material means having a high-speed flow characteristics, the use of ultrasonic agitation in the feed solution of liquid material to achieve homogeneous.

Specifications:

|

Model |

S-P20-1000 |

S-P20-1500 |

S-P20-2000 |

S-P20-3000 |

|

Frequency |

20±1 KHz |

20±1 KHz |

20±1 KHz |

20±1 KHz |

|

Power |

1000 W |

1500 W |

2000 W |

3000 W |

|

Voltage |

220±10% V |

220±10% V |

220±10% V |

220±10% V |

|

Temperature |

300 ℃ |

300 ℃ |

300 ℃ |

300 ℃ |

|

Pressure |

35 MPa |

35 MPa |

35 MPa |

35 MPa |

|

Intensity of sound |

>20 W/cm² |

>30 W/cm² |

>40 W/cm² |

>60 W/cm² |

|

Max Capacity |

> 10 L/Min |

> 15 L/Min |

> 20 L/Min |

> 30 L/Min |

|

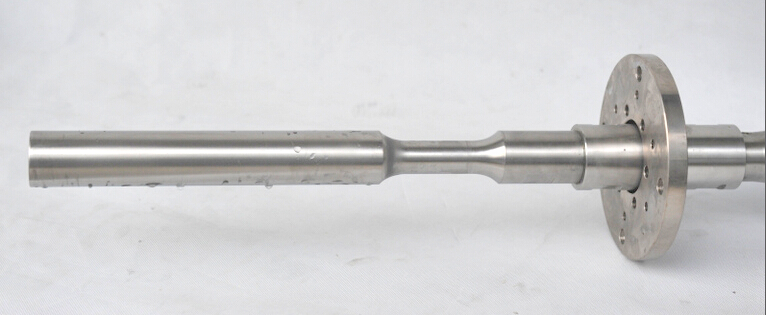

Material Of Tip Head |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

PS:If you need more power, we can install two or more device.

Competitive Advantage:

★ Without changing the customer production equipment and the existing process

★ Simple installation, the standard flange butt joint installation

★ Micro molecular interaction, direct, obvious effect

★ High power, high yield

★ Reduce cost, energy consumption

Previous :

High-Intensity Ultrasound Equipment For Crude Oil DesulfurizationNext :

Ultrasonic Processors For Liquid Degassing And DeaerationIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp