Advantages of Ultrasonic Sprayin

Compared with traditional two-fluid spraying, ultrasonic spraying has the advantages of high coating uniformity, high raw material utilization, high coating thickness control accuracy, thinner coating thickness, less splash, no clogging of nozzles, and low maintenance costs. Compared with vacuum evaporation, CVD and other coating processes, ultrasonic spraying is a more economical thin film coating process, especially for larger area film preparation. The cost of ultrasonic spraying equipment is much lower than that of vacuum coating equipment. Let us briefly introduce these main advantages of ultrasonic spraying.

High coating uniformity

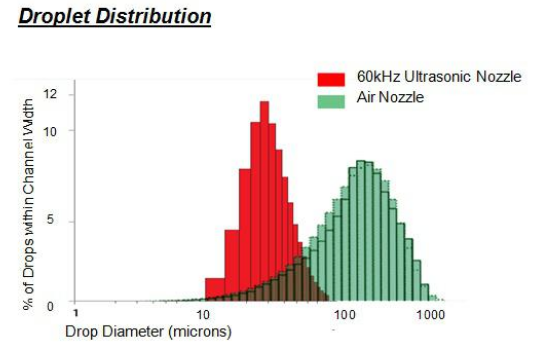

The uniformity of liquid particle distribution after being atomized by the ultrasonic nozzle is significantly higher than that of the two-fluid nozzle, also known as the air spray gun, so that the uniformity of the coating after the ultrasonic nozzle spraying is also significantly improved. Generally, the uniformity of ultrasonic spray coating can reach more than 95%.

2. High raw material utilization and less splash

Because ultrasonic spraying is liquid atomization by ultrasonic vibration, the coating is not atomized during the atomization process, that is, the atomization process does not require pressure, and only a very low carrier gas pressure is applied after the atomization to transport the liquid mist. It greatly reduces the liquid bounce and splash caused by high pressure air sprayed by two fluids, thereby greatly improving the utilization rate of the coating. The raw material utilization rate of ultrasonic spraying is more than 4 times that of ordinary air spraying, and the utilization rate can reach more than 90%.

3. High coating thickness control accuracy

The main factor that affects the coating thickness accuracy is the spray flow rate of the coating, that is, the amount of material carried on the substrate per unit time. The ultrasonic spray head does not have any pressure on the liquid, so it can completely control the liquid flow of the atomized spray coating by a high-precision metering pump, thereby achieving high-precision spray flow control. Such as a high-precision syringe pump, its flow control accuracy can reach the level of picoliters per second, and the micro-channel design of the ultrasonic nozzle can also achieve the overall control accuracy of nanoliters per second.

4. Thin coating thickness can reach tens of nanometers

Because the spray volume of the ultrasonic spray head can achieve a very low stable flow rate (0.001ml / min), it can achieve a very small upload amount on the substrate, thereby achieving a very thin dry film. For some nanomaterials, the dry film thickness can be as low as tens of nanometers. It can be used to prepare glass thin films such as transparent conductive film, anti-reflection anti-reflection film, heat-shielding film, and hydrophobic film.

5. No clogging of nozzles and low maintenance cost

Because the ultrasonic nozzle is a liquid atomized by ultrasonic oscillation, and the atomized particles are determined by the ultrasonic oscillation frequency, it is different from the two-fluid nozzle. The nozzle diameter does not need to be very small to achieve fine atomized particles, so it reduces The risk of nozzle clogging.

Previous :

Crazy medical mask machineNext :

Ultrasonic Turning© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat