Graphene is composed By carbon atoms lined closely in hexagonal honeycomb lattice of single-layer two dimensional planar structure,was the basic structure of fullerenes, carbon nanotubes and graphite, so it is called the mother of carbon materials

Product origin:

ChinaProduct weight:

17Kg

| Minimum Order Quantity: |

1 Set |

| Price: |

|

| Packaging Details: |

Wooden Case |

| Delivery Time: |

15 Working Days |

| Payment Terms: |

T/T, WESTERN UNION |

| Supply Ability: |

50 Sets/Month |

Quick Detail:

Simple, low-cost design

Low operating costs

High efficiency

Low maintenance

Faster emulsification

Description:

Graphene is composed By carbon atoms lined closely in hexagonal honeycomb lattice of single-layer two dimensional planar structure,was the basic structure of fullerenes, carbon nanotubes and graphite, so it is called the mother of carbon materials

Introduce:

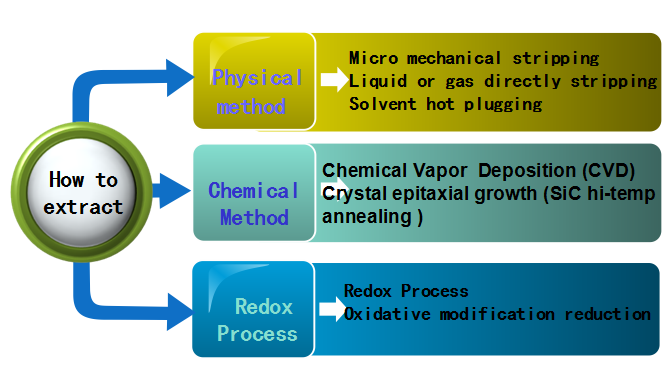

Micro mechanical stripping:Mechanical strip the graphite layers, high quality graphene, But low output and high cost,can't meet the industrialized production.

Chemical Vapor Deposition (CVD): Substances in gas envirement will react, generate solids deposition on the surface of the heating solid substrate(usually nickel),it can produce large area high quality graphene, But because the basic material (nickel) expensive, so the price went up, also does not meet the industrialization.

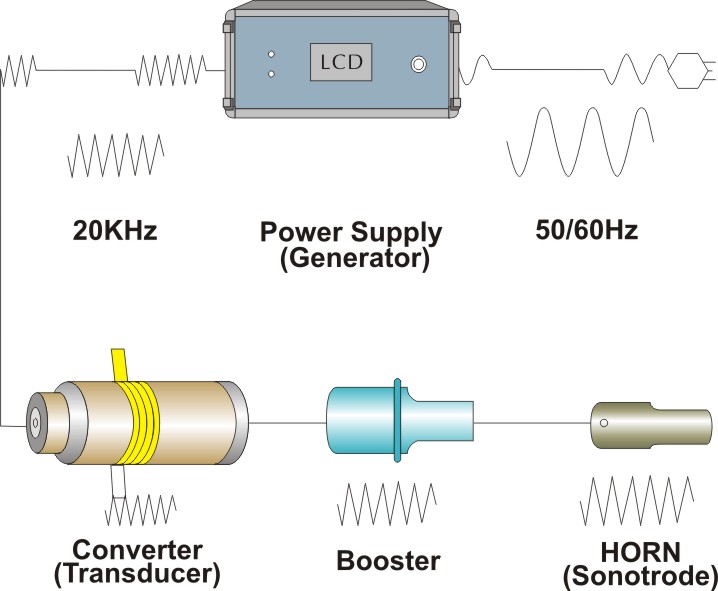

Solvent hot plugging: Mix the graphite powder and intercalating agent,and then dealing by ultrasonic equipment, the quality is well but the quantity is lower.

Redox Process:Firstly of preprocess the graphite to conver it to graphite oxide, meaningtime the gap of Graphite oxide layer will increase, then dealing by ultrasonic dispersion process, get a single layer of graphite oxide.Then by reduction reaction, single layer of graphite oxide reduction into graphene. This method is the most common way. The method of Oxidation and reduction is multiply.

Competitive Advantage:

★ Save time 20%~60%

★ Less methanol 5%~30%

★ Less chemical (KOH) less 20%~50%

★ Total production cost save 15%~50%

★ Another benefit is the time of glycerol separation.This is also faster and one of the reasons for it is that less methanol is been used,so glycerol separation is faster.

Previous :

1500W Ultrasonic Herb Extract EquipmentIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2025 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp